- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

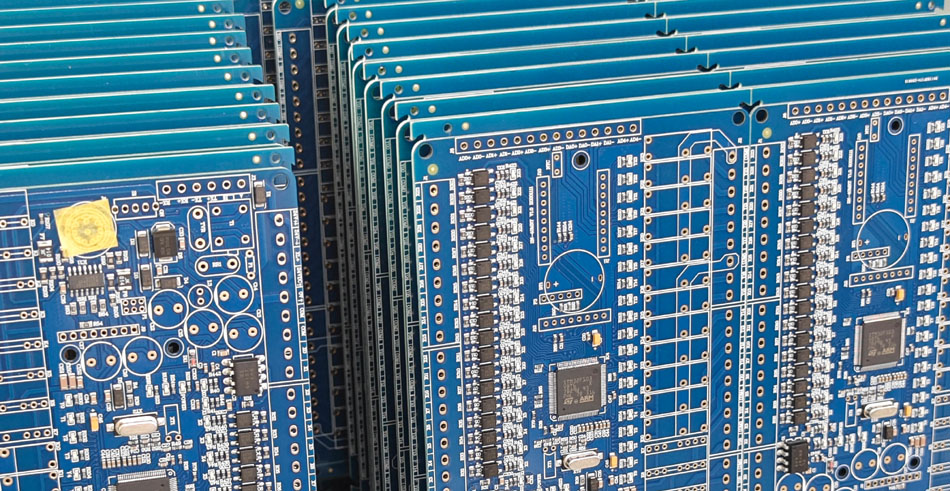

Exploring the Customization Capabilities of PCBA Factories

In the rapidly developing electronics manufacturing industry, increasing customer demand for personalization and customization is driving innovation and transformation in the service capabilities of PCBA (Printed Circuit Board Assembly) factories. Customization not only meets specific customer needs but also enhances product competitiveness. This article will explore the customization capabilities of PCBA factories.

1. The Importance of Customization

Meeting Diverse Needs

Modern customers are increasingly prioritizing customization when selecting PCBA factories. Different industries and application scenarios have varying requirements for PCB design, size, and functionality, and PCBA factories need flexible production capabilities to meet these diverse needs.

Improving Customer Satisfaction

Providing customized services enhances customer engagement and satisfaction. When customer needs are promptly addressed and met, they are more likely to establish long-term relationships with PCBA factories.

2. The Customization Service Process

Requirements Communication and Analysis

The first step in providing customized services is in-depth communication with the customer. PCBA factories need to understand their specific needs in detail, including functionality, materials, dimensions, and delivery time. Through professional analysis, factories can provide practical solutions.

Design and Prototyping

After clarifying customer requirements, the PCBA factory will design the PCBs. This process typically requires the use of professional design software and adjustments based on customer requirements. Once the design is complete, the factory will produce samples for customer verification to ensure the final product meets expectations.

3. Production and Quality Control

Flexible Production Scheduling

PCBA factories should have flexible production scheduling capabilities to accommodate changes in customized orders. During the production process, the factory can adjust according to customer needs to ensure a balance between production efficiency and quality.

Strict Quality Control

Customized services place particularly stringent quality requirements. PCBA factories should establish a comprehensive quality control system and rigorously test each batch of products to ensure performance and reliability. By implementing comprehensive quality management, the factory can provide customers with a reliable guarantee upon delivery.

4. Customer Feedback and Continuous Improvement

Collecting Customer Feedback

After product delivery, PCBA factories should proactively collect customer feedback. This feedback not only helps the factory understand the product's performance but also identifies potential issues, providing a basis for subsequent improvements.

Continuous Service Optimization

By analyzing customer feedback, PCBA factories can continuously optimize their customized service processes. These improvements may include increasing response speed, increasing technical support, and refining production processes to better meet customers' individual needs.

5. Future Development Directions

Introducing New Technologies

With the continuous advancement of technology, PCBA factories should actively introduce new technologies, such as intelligent manufacturing and data analytics. These technologies can improve production efficiency and provide more precise customized services.

Expanding the Scope of Cooperation

In the future, PCBA factories can also consider collaborating with customers in more industries to broaden their customized service offerings. With a diversified customer base, factories can better adapt to market changes and enhance their competitiveness.

Conclusion

Exploring PCBA factories' customized service capabilities is not only a necessary step to meet market demand but also a crucial means to improve customer satisfaction and enhance market competitiveness. Through comprehensive service processes, flexible production capabilities, and continuous improvement measures, PCBA factories can continue to advance on the path of customized services and achieve higher value and growth.

Send Inquiry

-

Delivery Service

-

Payment Options