- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

How can PCBA factories address environmental challenges through green manufacturing strategies?

2025-09-26

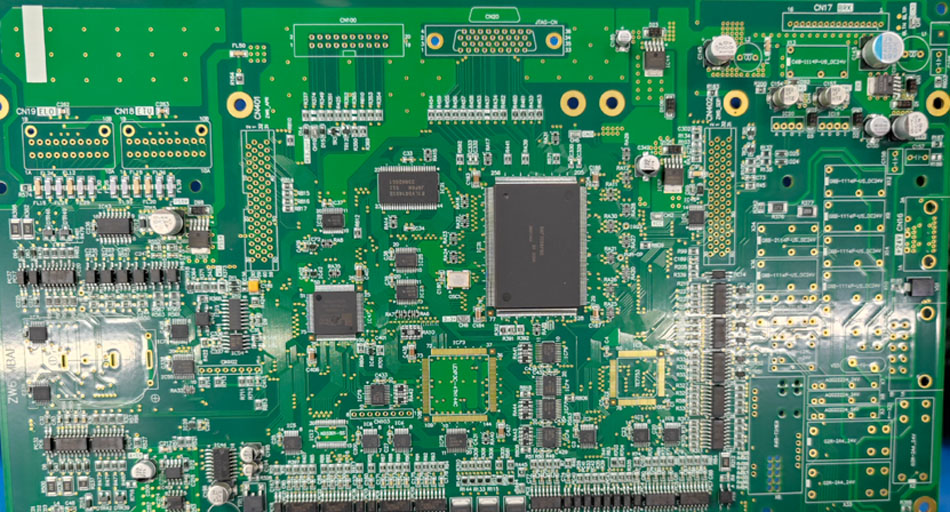

Globally, environmental awareness is growing, and green manufacturing has become a key trend across various industries. For PCBA (Printed Circuit Board Assembly) factories, facing increasingly stringent environmental regulations and customer requirements, implementing green manufacturing strategies has become an effective way to address these challenges. This article will explore how PCBA factories can address these challenges and achieve sustainable development through green manufacturing strategies.

1. Understanding the Definition of Green Manufacturing

What is Green Manufacturing?

Green manufacturing refers to a production approach that minimizes negative environmental impacts and improves resource efficiency across all stages of the process, including product design, material selection, production processes, product use, and waste disposal. Its core concept is to achieve a win-win situation in both economic and environmental benefits with minimal resource consumption and environmental impact.

The Importance of Green Manufacturing in PCBA Processing

PCBA processing typically involves significant material and energy consumption, and may generate hazardous waste. Therefore, promoting green manufacturing not only helps reduce production costs but also enhances a company's social image and market competitiveness.

2. Green Manufacturing Strategies for PCBA Factories

Selecting Environmentally Friendly Materials

PCBA factories should prioritize materials that meet environmental standards. For example, using lead-free solder instead of traditional solder reduces the harm of lead to the environment and human health. Furthermore, selecting recyclable and biodegradable materials reduces resource waste and environmental impact.

Optimizing Production Processes

By introducing advanced production processes, PCBA factories can improve production efficiency and reduce energy consumption. For example, automated production lines and intelligent manufacturing technologies can reduce manual errors, improve production efficiency, and reduce waste. Furthermore, implementing lean production methods can optimize production processes and eliminate unnecessary steps, thereby reducing resource waste.

Strengthening Waste Management

PCBA factories need to establish a comprehensive waste management system to ensure effective waste sorting and treatment. Recycling waste generated during the production process, such as circuit board cutting residues and packaging materials, can reduce raw material procurement costs and minimize environmental pollution. Furthermore, factories should actively explore ways to reuse waste, turning waste into valuable resources.

3. Technical Support for Green Manufacturing

Using Environmentally Friendly Equipment

PCBA factories should prioritize equipment that meets environmental standards. This equipment not only reduces energy consumption but also minimizes harmful emissions during production. For example, using low-energy, high-efficiency ovens and cleaning equipment can significantly reduce energy consumption during production.

Data Monitoring and Analysis

By implementing smart manufacturing and IoT technologies, PCBA factories can monitor resource consumption and waste generation during production in real time. Using data analysis, factories can identify resource shortfalls and adjust production strategies accordingly, achieving more efficient resource management.

4. Employee Training and Awareness Raising

Strengthening Environmental Awareness Training

To effectively implement green manufacturing strategies, PCBA factories should regularly provide employee training on environmental awareness and green manufacturing knowledge. Raising employee awareness will help them consciously adhere to environmental regulations during production, reducing resource waste and environmental pollution.

Establishing a Green Culture

Factories can foster a green culture by encouraging employees to make environmental recommendations and actively participate in green manufacturing practices. Through internal publicity and recognition mechanisms, we can enhance the sense of participation and responsibility among all employees and foster a positive environmental atmosphere.

Conclusion

Faced with increasingly severe environmental challenges, PCBA factories can effectively reduce the environmental impact of production and improve resource efficiency by implementing green manufacturing strategies. PCBA factories should continuously explore and innovate in areas such as selecting environmentally friendly materials, optimizing production processes, strengthening waste management, adopting environmentally friendly equipment, and raising employee environmental awareness. Through these efforts, factories can not only meet environmental regulations but also gain an advantage in the fiercely competitive market and achieve sustainable development. Therefore, green manufacturing strategies will become a key development direction for PCBA factories in the future.

-

Delivery Service

-

Payment Options