- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

The Importance of Environmental Compliance for PCBA Factories: RoHS and REACH Analysis

2025-09-24

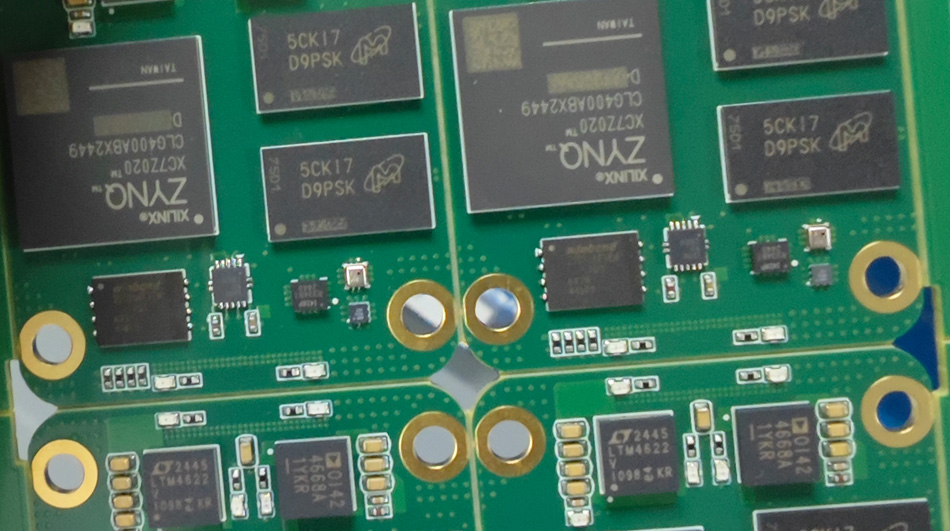

Environmental compliance is gaining increasing attention in the modern electronics manufacturing industry. For PCBA (Printed Circuit Board Assembly) factories, compliance with relevant environmental regulations such as RoHS (Restriction of Certain Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) is not only a legal obligation but also crucial for enhancing market competitiveness and corporate image. This article will analyze the importance of RoHS and REACH and their impact on PCBA processing.

1. Overview and Impact of RoHS

Overview of RoHS Regulations

RoHS is a directive issued by the European Union in 2003 that restricts the use of certain hazardous substances in electrical and electronic equipment. Under RoHS regulations, electronic products manufactured and sold must not contain hazardous substances such as lead, mercury, cadmium, hexavalent chromium, polybrominated biphenyls (PBBs), and polybrominated diphenyl ethers (PBDEs) exceeding specified limits.

The Impact of RoHS on PCBA Factories

For PCBA factories, compliance with RoHS regulations is a fundamental requirement for ensuring product compliance and market access. Only products that meet RoHS standards can be sold in the European market. Furthermore, many countries and regions have also implemented similar regulations, making RoHS compliance a crucial requirement in the global market. PCBA factories must ensure that all materials and components used in the production process comply with RoHS standards. This not only reduces environmental pollution but also enhances corporate social responsibility and brand image.

2. Overview and Impact of REACH

Overview of REACH

REACH is a chemical management regulation implemented by the European Union in 2007 that requires manufacturers and importers to register, evaluate, and authorize chemicals when producing and selling them. REACH covers a wide range of chemical substances, including those potentially used in PCBA processing. Its goal is to ensure the safe use of chemicals and protect human health and the environment.

Impact of REACH on PCBA Factories

PCBA factories need to understand and comply with REACH to ensure the compliance of all chemicals used. For production processes using chemicals, such as cleaning agents and soldering materials, manufacturers must provide relevant Safety Data Sheets (SDSs) and assess the potential risks these chemicals pose to the environment and human health. Compliance with REACH not only reduces legal risks but also increases customer trust in companies, thereby enhancing market competitiveness.

3. Economic Benefits of Compliance

Reducing Legal Risk

Compliance with RoHS and REACH regulations can effectively reduce legal risks arising from non-compliance. The consequences of non-compliance can include significant fines, product recalls, and damage to a company's reputation. By ensuring compliance, PCBA factories can avoid these potential losses and achieve long-term, stable development.

Improving Market Competitiveness

Environmental compliance is not only a legal requirement but also a crucial factor in market competition. More and more customers are considering environmental compliance when selecting suppliers. If PCBA factories can display RoHS and REACH compliance markings on their products, they will help attract more customers, especially in the European and American markets.

4. Compliance Practice and Implementation

Establishing a Compliance Management System

To ensure RoHS and REACH compliance, PCBA factories should establish a comprehensive compliance management system. This includes auditing the supply chain to ensure that all raw materials and components meet relevant standards. Furthermore, regular internal audits and training should be conducted to enhance employee awareness and knowledge of environmental compliance.

Continuous Improvement and Innovation

Environmental regulations are constantly evolving, and PCBA factories should remain sensitive to regulatory changes. By continuously improving production processes and material selection, factories can not only maintain compliance but also achieve environmental innovation. This innovative capability will bring new market opportunities and competitive advantages to factories.

Conclusion

Environmental compliance is crucial in PCBA processing. Compliance with RoHS and REACH regulations is not only a legal obligation but also a manifestation of enhancing corporate competitiveness and social responsibility. By establishing an effective compliance management system, reducing legal risks, and improving market competitiveness, PCBA factories can achieve sustainable development in an increasingly competitive market. Therefore, focusing on environmental compliance will become the key to the success of future PCBA factories.

-

Delivery Service

-

Payment Options