- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

PCBA Factory Success Case Study: Key Factors in Partner Selection

2025-09-19

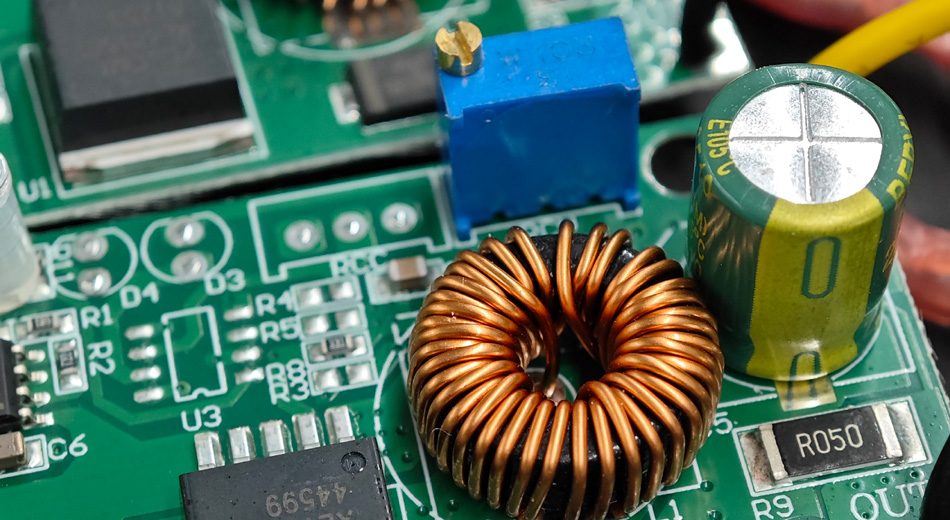

In the rapidly growing electronics manufacturing industry, choosing the right PCBA (Printed Circuit Board Assembly) factory partner is crucial to a company's success. The right partner not only ensures product quality and delivery timelines, but also provides innovative solutions, helping companies stand out from the competition. This article will explore key factors to consider when selecting a PCBA partner through successful case studies.

1. Quality Control and Certification

Successful Case Study: A High-Tech Company's Partnership with a PCBA Factory

When selecting a PCBA manufacturing partner, a high-tech company prioritized quality control. After researching several factories, they ultimately selected a PCBA factory certified to ISO 9001 and IPC-A-610. This factory strictly implements a quality management system, monitoring every production step to ensure that products meet international standards. This partnership has resulted in significant improvements in product quality and increased customer satisfaction.

Key Factor: Reviewing Certifications and Quality Control Procedures

When selecting a PCBA factory, companies should focus on the factory's quality certifications and control procedures. Certification is a strong indicator of a factory's quality management, and a sound quality control process ensures product consistency and reliability.

2. Technical Capabilities and Innovation

Successful Case Study: Emerging Technology Company Breaks into the Market

Another emerging technology company, when selecting a PCBA manufacturing partner, paid particular attention to the factory's technical capabilities and innovation. They chose a PCBA factory specializing in automated production and intelligent manufacturing. Through close collaboration, the factory helped the company shorten production cycles and achieve rapid product iteration. Ultimately, the emerging technology company successfully launched a market-leading smart device.

Key Factor: Assessing Technical Strength and R&D Capabilities

Technical capabilities and innovation are important criteria for selecting a PCBA factory. Companies should examine the factory's performance in new technology application, product development, and improvement to ensure it can meet future market demands.

3. Cost-Effectiveness and Delivery Capabilities

Successful Case Study: Transformation of Traditional Manufacturing

A traditional manufacturing company prioritized cost-effectiveness and delivery capabilities when selecting a PCBA factory. They ultimately selected a factory that offered reasonable pricing and fast delivery. By optimizing production processes and strengthening supply chain management, the factory successfully reduced production costs and ensured on-time delivery. As a result, this traditional enterprise not only successfully transformed but also gained a competitive advantage in new markets.

Key Factor: Considering Cost and Delivery Capabilities

When selecting a PCBA factory, companies should consider both cost-effectiveness and delivery capabilities. Reasonable pricing and stable delivery capabilities can ensure smooth project execution and reduce operational risks.

4. Customer Service and Support

Successful Case Study: Collaboration in the Medical Device Industry

Customer service and technical support are crucial in the medical device industry. When selecting a PCBA factory, a medical device company placed particular emphasis on after-sales service and technical support. They chose a factory with a strong customer support team to ensure timely resolution of issues during the production process. The factory not only provided comprehensive technical support but also proactively responded to customer needs, ultimately helping the medical device company successfully launch its new product.

Key Factor: Evaluating Customer Service and Technical Support

When selecting a PCBA factory, it is crucial to evaluate its customer service and technical support capabilities. Excellent customer service can increase project success rates and ensure that companies receive timely and effective assistance during the production process.

5. Environmental Compliance and Social Responsibility

Successful Case Study: The Rise of Green Electronics

With the continuous strengthening of environmental regulations, selecting a PCBA factory that meets environmental standards has become a key consideration for companies. When selecting a partner, an electronics company paid particular attention to the factory's environmental compliance and social responsibility. They ultimately chose a PCBA factory that practiced green production, was compliant with RoHS and REACH standards, and actively participated in social responsibility programs. This choice not only enhanced the company's social image but also won the favor of a growing number of environmentally conscious consumers.

Key Factors: Focusing on Environmental Compliance and Social Responsibility

When selecting a PCBA factory, companies should pay attention to its environmental compliance and social responsibility. Factories that meet environmental standards not only reduce legal risks but also enhance their brand image and attract more customers.

Conclusion

Choosing the right PCBA factory as a partner is crucial to a company's success. The above successful case study demonstrates that when selecting a partner, companies should prioritize key factors such as quality control, technical capabilities, cost-effectiveness, customer service, and environmental compliance. Only by comprehensively evaluating these factors can they ensure they find the most suitable PCBA processing partner and achieve mutual development and success.

-

Delivery Service

-

Payment Options