- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

How Lean Management Strategies in PCBA Factories Help Control Costs

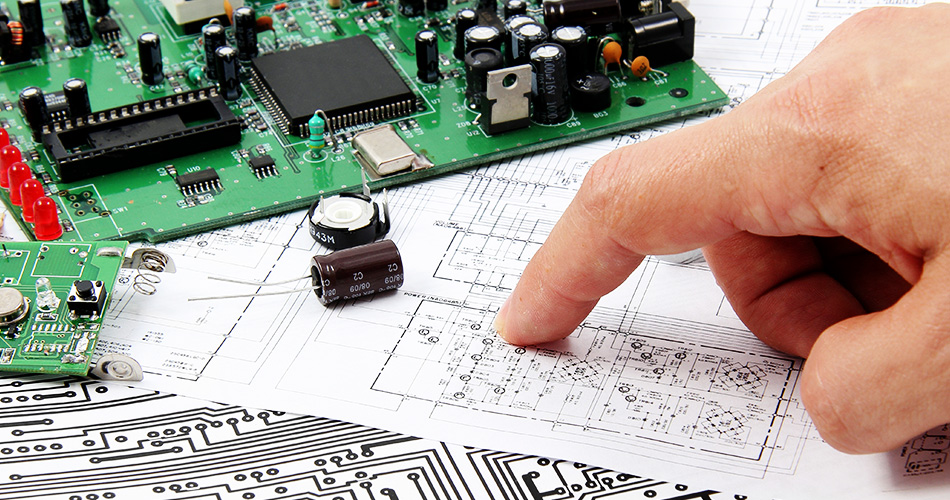

In today's highly competitive electronics industry, PCBA (Printed Circuit Board Assembly) factories face increasing cost pressures. To maintain market competitiveness, many companies are implementing lean management strategies to effectively control costs and improve efficiency. This article will explore how PCBA factories can achieve cost control and ensure product quality and delivery capabilities through lean management strategies.

1. Basic Concepts of Lean Management

Lean management originated from Japan's Toyota Production System. Its core concept is to maximize corporate value by eliminating waste, optimizing processes, and improving production efficiency. In PCBA manufacturing, lean management can not only reduce production costs but also improve product quality and customer satisfaction.

2. Eliminating Waste and Improving Efficiency

Identifying and Eliminating Waste

Common waste in PCBA manufacturing includes excessive inventory, waiting times, transportation, and process redundancy. Through lean management, companies can comprehensively review their production processes, identify waste at every stage, and then take measures to eliminate it. For example, a Kanban system can be used to control inventory levels, avoid excessive material backlogs, and reduce capital and storage costs.

Continuous Process Improvement

Lean management emphasizes continuous improvement. PCBA factories can continuously optimize production processes and improve efficiency by implementing the PDCA (Plan-Do-Check-Act) cycle. Regular process assessments and employee training can identify potential issues and make timely adjustments, ensuring smooth production and improving resource utilization.

3. Optimizing Production Layout

Production Line Design

Lean management also involves optimizing production line layout. In PCBA processing, a reasonable production line layout can shorten worker travel distances, reduce unnecessary transportation time, and improve production efficiency. Furthermore, centralizing similar processes can help reduce equipment changeover time and further enhance production flexibility.

Equipment Management

Lean management requires the proper management and maintenance of equipment. In PCBA factories, regular equipment inspection and maintenance can prevent production downtime caused by equipment failures and reduce the additional costs associated with equipment problems. Furthermore, efficient equipment utilization can reduce the production cost per product.

4. Improving Employee Engagement

Employee Training and Motivation

Lean management emphasizes employee engagement and training. During the PCBA manufacturing process, companies should regularly provide employees with lean management training to enhance their awareness of quality and efficiency. Incentive mechanisms should be implemented to encourage employees to submit improvement suggestions, fostering a positive corporate culture that empowers employees to proactively identify and implement improvements.

Teamwork

Teamwork is key to the success of lean management. In PCBA factories, establishing cross-departmental collaborative teams can effectively resolve production issues and improve communication and collaboration across all links. This collaboration not only helps control costs but also improves product quality and enhances customer satisfaction.

5. Data-Driven Decision-Making

Real-Time Monitoring and Data Analysis

Data-driven decision-making is a key component of lean management. PCBA factories can monitor production data in real time and analyze the efficiency and cost of each link, enabling them to make informed decisions. For example, by analyzing data such as production cycle time and material consumption, they can identify key cost control areas and adjust production strategies in a timely manner.

Forecasting and Planning

Using data analysis tools, PCBA factories can conduct demand forecasting and production planning. Accurate demand forecasting allows companies to effectively control inventory and reduce production costs, ensuring they meet customer needs without incurring excessive inventory costs.

Conclusion

In summary, lean management strategies are crucial for cost control in PCBA manufacturing. By eliminating waste, optimizing production processes, enhancing employee engagement, and making data-driven decisions, PCBA factories can effectively reduce production costs and improve product quality and delivery capabilities. In an increasingly competitive market, implementing lean management is not only an effective means of reducing costs but also a crucial path to enhancing competitiveness. Through continuous lean improvement, PCBA factories will remain competitive in the industry.

Send Inquiry

-

Delivery Service

-

Payment Options