- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

How does quality control in PCBA factories affect product life?

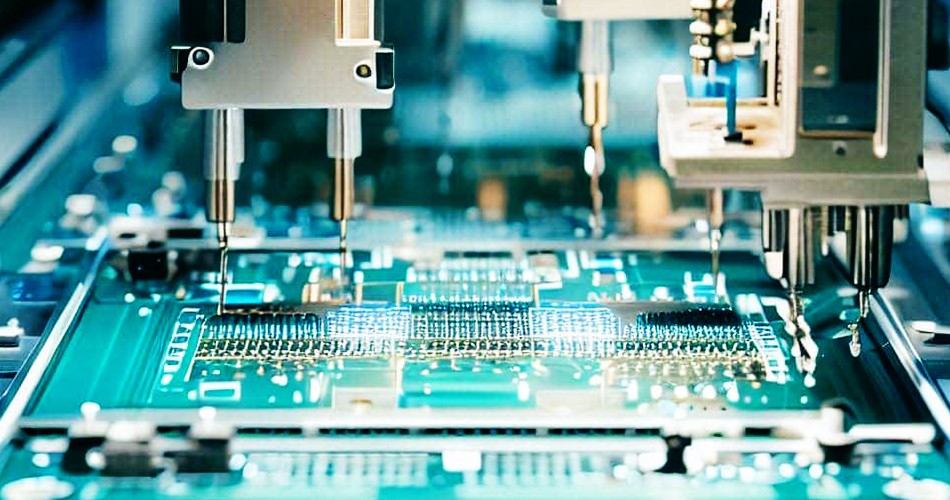

During the PCBA (Printed Circuit Board Assembly) processing, quality control is one of the key factors affecting product life. PCBA factories use strict quality management systems, advanced testing equipment and scientific production processes to ensure that every detail meets the standards, which directly affects the service life of electronic products. This article will explore how quality control in PCBA processing can significantly improve product life and analyze the importance of each key link.

1. Strict selection and management of raw materials

High-quality substrate materials

Quality control in PCBA processing begins with the selection of raw materials, especially the quality of substrate materials directly determines the durability and stability of circuit boards. High-quality substrate materials have good heat resistance, moisture resistance and insulation, which can effectively reduce the aging, deformation or electrical failure of circuit boards during long-term use. By selecting raw material suppliers that meet international standards, PCBA factories can ensure the life of products from the source.

The quality of solder affects soldering strength

soldering quality plays a vital role in the reliability of PCBA processing. High-performance lead-free solder can not only improve the strength of solder joints, but also enhance their oxidation resistance and corrosion resistance, reducing the risk of failure when used in complex environments. PCBA factories with strict quality control will conduct strict tests on solder to ensure the stability and reliability of the soldering process.

2. Advanced manufacturing processes and equipment

Precise assembly process

The assembly process in PCBA processing directly affects the performance and life of the product. Precise assembly process requires the factory to have advanced SMT (surface mount technology) and reflow soldering equipment to ensure that each component can be accurately positioned and firmly connected. The introduction of advanced equipment and the optimization of process parameters can effectively reduce problems such as solder joint virtual connection and component offset, and extend the service life of the product.

Temperature and humidity control

The production environment control of the PCBA factory has an important impact on the life of the product. During the processing, changes in temperature and humidity may cause unstable performance of solder and components, thereby shortening the life of the product. By controlling temperature and humidity in a clean environment, the factory can greatly improve the overall quality of PCBA processing and ensure that the product can maintain long-term stability in harsh environments.

3. Multi-level detection methods and process control

Automatic optical inspection (AOI) and X-ray inspection (AXI)

In PCBA processing, multi-level detection methods are one of the cores to ensure product quality. Automatic optical inspection (AOI) can quickly identify problems such as poor soldering and component defects, ensuring that each circuit board is flawless before entering the next process. For multi-layer circuit boards, X-ray inspection (AXI) can go deep into the board layer to ensure that there are no problems with each via and internal connection, thereby avoiding potential failures in subsequent use.

Electrical performance test

Electrical performance testing is an important part of evaluating the quality of PCBA processing. Through flying probe testing (Flying Probe) and functional testing (FCT), PCBA factories can verify whether the electrical connectivity and function of each circuit board are normal. This type of test can not only eliminate problems such as short circuits and open circuits in the circuit board, but also ensure its long-term stability in complex electrical environments.

4. Continuous quality improvement and feedback mechanism

ISO-certified quality management system

The quality management system is an important guarantee for PCBA factories to maintain high-quality production. By obtaining international certifications such as ISO9001, factories can implement standardized production processes and continuously improve their quality control systems. Such a management system ensures that each production link can strictly follow quality standards, thereby reducing the generation of defective products and extending the service life of products.

Customer Feedback and Quality Improvement

Continuous quality improvement is inseparable from customer feedback. By collecting customer feedback on product use in a timely manner, PCBA factories can discover potential quality problems and further improve product life by adjusting process flow and improving quality inspection methods. Such a closed-loop feedback mechanism can effectively improve PCBA processing quality and ensure that products maintain excellent performance in the fierce market competition.

Conclusion

The quality control of PCBA factories directly affects the service life of products. From the selection of raw materials to precise manufacturing processes, to strict testing and continuous improvement, every link determines the reliability of the product. High quality control in PCBA processing can not only improve product performance, but also significantly extend its service life. In today's fierce market competition, only through strict quality control can PCBA factories provide customers with high-quality products and stand out in the industry.

Send Inquiry

-

Delivery Service

-

Payment Options