- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Explore the improvement of production quality by automated soldering technology in PCBA factories

2025-07-30

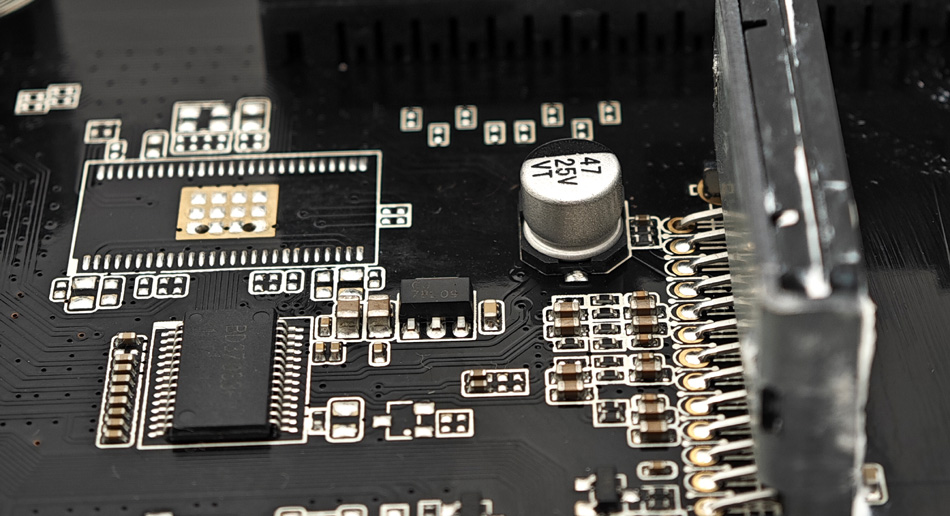

In the modern electronic manufacturing industry, PCBA processing (Printed Circuit Board Assembly) is a crucial link, and the soldering process is a key factor affecting product quality. With the advancement of technology, automated soldering technology has gradually replaced traditional manual soldering and become an important means for PCBA factories to improve production quality. This article will explore how automated soldering technology can improve production quality in PCBA processing.

1. Definition and development of automated soldering

Automated soldering refers to the technology of automatically completing the soldering process using mechanical equipment and intelligent systems. This soldering method not only improves soldering efficiency, but also reduces labor costs. In recent years, with the rise of intelligent manufacturing and Industry 4.0, more and more PCBA factories have begun to introduce automated soldering equipment, such as laser soldering, spot soldering, reflow soldering, etc., to improve production efficiency and product quality.

2. Advantages of automated soldering technology

Improve soldering accuracy

Automated soldering equipment has a high degree of accuracy and can perform soldering according to preset parameters. This consistency significantly reduces soldering defects caused by human factors and improves the reliability of solder joints. For example, during the reflow soldering process, automated equipment can accurately control the temperature curve and time to ensure uniform melting of the solder and avoid problems such as cold cracking of the soldering.

Reduce defect rate

Traditional manual soldering is easily affected by workers' skills, fatigue and environmental factors, resulting in soldering defects. Automated soldering technology can automatically detect soldering quality and adjust soldering parameters in time through a real-time monitoring system, thereby effectively reducing the defect rate. This is crucial to improving the overall quality of PCBA processing.

3. Application of automated soldering in PCBA processing

Reflow soldering

Reflow soldering is one of the commonly used automated soldering methods in PCBA processing. By placing the PCB with mounted components into the reflow soldering furnace, heat is used to melt and solidify the solder to form a soldering connection. Reflow soldering not only increases the soldering speed, but also effectively prevents damage to components caused by improper soldering, thereby improving the overall quality of the product.

Laser soldering

Laser soldering is a high-precision soldering technology that is particularly suitable for high-density and high-precision PCBA processing. Laser soldering can quickly heat the soldering point and reduce the heat-affected zone, thereby effectively reducing damage to components during the soldering process. This technology is particularly prominent in the production of high-end electronic products, and can ensure the high quality and stability of soldering.

4. The impact of automated soldering on production efficiency

Automated soldering technology has significantly improved the production efficiency of PCBA processing. By reducing manual intervention, the operation time in the soldering process is reduced, and large-scale soldering tasks can be completed in a short time. This is of great significance for meeting customers' requirements for delivery cycles and improving the market competitiveness of enterprises.

5. Continuous improvement and future prospects

Although automated soldering technology has achieved remarkable results in PCBA processing, it still needs to continue to improve and innovate technology. With the development of technologies such as artificial intelligence and the Internet of Things, future automated soldering equipment will be more intelligent and flexible, able to monitor the production process and analyze data in real time, and further improve soldering quality and production efficiency.

Conclusion

Automated soldering technology is an important means to improve the quality of PCBA processing. It not only improves soldering accuracy and reduces defect rate, but also significantly improves production efficiency. By continuously introducing and optimizing automated soldering technology, PCBA factories can better meet market demand and improve product competitiveness. Facing the future, continuous technological innovation and equipment upgrades will be the key to promoting the improvement of PCBA processing quality.

-

Delivery Service

-

Payment Options