- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

How do PCBA factories cope with the production needs of highly complex circuit designs?

2025-07-28

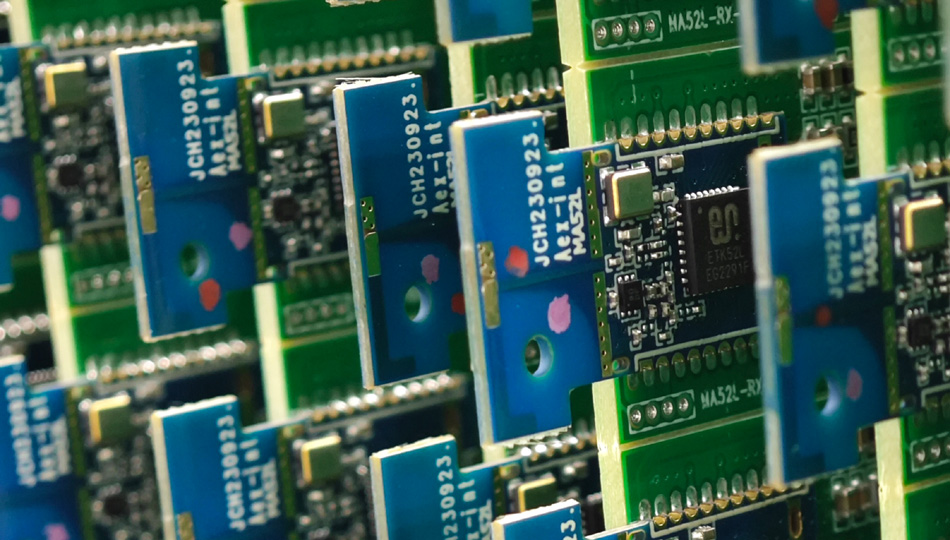

With the rapid development of science and technology, the complexity of electronic products continues to increase, and the application of highly complex circuit designs in PCBA processing (Printed Circuit Board Assembly) is becoming more and more common. To cope with this complexity, PCBA factories need to take a series of measures to ensure production efficiency and product quality. This article will explore how PCBA factories can effectively cope with the production needs of highly complex circuit designs.

1. Use advanced design tools

Application of CAD/CAM software

Modern PCBA factories often use advanced computer-aided design (CAD) and computer-aided manufacturing (CAM) software, which can help engineers quickly design and optimize circuits. By using CAD tools, designers can effectively handle complex circuit layouts, achieve higher density component arrangements, and perform real-time design verification. This not only shortens the design cycle, but also reduces the cost of modifications in later production.

3D modeling technology

3D modeling technology also plays an important role in the design of highly complex circuits. Through three-dimensional modeling, engineers can better analyze the spatial layout and thermal management issues of circuit boards, thereby optimizing design solutions and ensuring the functionality and reliability of circuits.

2. Strengthening production process

High-precision mounting technology

The key to coping with high-complexity circuit design lies in the improvement of production process. High-precision mounting technology can ensure the precise position and mounting quality of micro components, and avoid circuit failures caused by improper mounting. Many PCBA factories have introduced automated placement machines that can achieve high-precision mounting at high speeds, thereby improving production efficiency and product consistency.

Production capacity of multi-layer circuit boards

High-complexity circuit design often requires the support of multi-layer circuit boards. PCBA factories need to have mature multi-layer circuit board processing capabilities, including inter-layer connections, fine processing of inner layer lines, etc. By optimizing production processes and process parameters, factories can improve the production quality of multi-layer circuit boards to ensure that the needs of high-complexity designs are met.

3. Strengthening quality control

Real-time monitoring and detection

When producing highly complex circuits, real-time monitoring and detection are essential. PCBA factories can introduce intelligent manufacturing systems to collect production data in real time and monitor various parameters in the production process. This real-time monitoring can detect potential problems in a timely manner, so that rapid adjustments can be made to ensure the stability of the production process and product quality.

Final inspection and functional testing

For highly complex circuit designs, it is particularly important to conduct comprehensive final inspection and functional testing. The factory should establish a complete testing system, including a combination of automated testing equipment and manual testing methods, to ensure that each circuit board undergoes strict quality inspection before leaving the factory. By implementing strict quality control, the factory can effectively reduce the defective rate and improve customer satisfaction.

4. Training professional talents

Improve employee skills

Faced with highly complex circuit designs, PCBA factories must focus on employee skills training. Regular technical training to help employees master the latest production processes, equipment operations and quality control methods is an important way to improve production capacity. By cultivating professional talents, the factory can better cope with complex production needs and ensure the smooth progress of the production process.

Cross-departmental collaboration

In the production process of highly complex circuit designs, multiple departments such as design, production and quality control need to work closely together. Establishing a cross-departmental collaboration mechanism to promote information sharing and communication can improve work efficiency, quickly respond to problems in production, and ensure the smooth progress of the project.

Conclusion

Highly complex circuit design has put forward higher production requirements for PCBA processing. PCBA factories should effectively respond to this challenge by adopting advanced design tools, strengthening production processes, strengthening quality control, and training professional talents. Only by continuously improving their own technical capabilities and management levels can they remain invincible in the fierce market competition. With the continuous advancement of technology, the future of PCBA factories will be brighter.

-

Delivery Service

-

Payment Options