- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

How can PCBA factories reduce costs through automated production?

2025-07-16

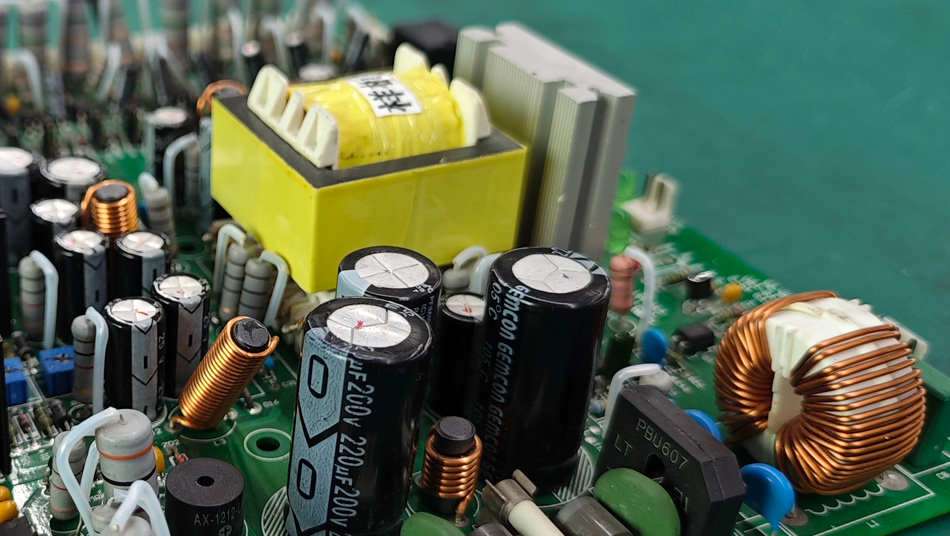

In the field of PCBA processing, reducing production costs is one of the important means for factories to enhance their market competitiveness. With the continuous advancement of technology, automated production technology has gradually become a core tool for PCBA factories to reduce costs and improve efficiency. This article will discuss in detail how PCBA factories can optimize their cost structure through automated production to help companies gain advantages in the fierce market competition.

1. How does automated production reduce labor costs

Reduce labor demand and reduce labor expenses

One of the biggest advantages of automated production is to reduce the demand for manpower. In PCBA processing, many traditional production links require a lot of manual operations, and high precision requirements, which are prone to human errors. Through automated equipment, such as automatic placement machines, soldering robots, etc., PCBA factories can significantly reduce their dependence on operators, reduce labor costs, and improve production efficiency.

Reduce the rework rate caused by human errors

Automated production can not only save labor costs, but also reduce the rate of human errors. In PCBA processing, automated equipment can perform operations according to preset precise instructions, reduce human intervention, make product assembly, placement and other processes more stable and accurate, and significantly reduce rework and repair costs.

2. Automation improves production efficiency and shortens production cycle

Increase production speed and shorten delivery cycle

Automated equipment can operate uninterruptedly and at high speed, thereby shortening the production cycle of products. For example, the speed of automatic placement machines is several times faster than manual operation, and large quantities of components can be placed in a short time. The shortened production cycle means that the factory can complete orders faster, improve customer satisfaction, and reduce inventory costs caused by waiting time.

Multi-process synchronous processing to improve overall production capacity

In PCBA processing, automated equipment can support multiple processes simultaneously, such as placement and soldering, which can be run simultaneously in different equipment. Through a reasonable layout of automated production lines, PCBA factories can synchronize production processes, improve overall production capacity, and reduce the unit cost of each batch of products.

3. Reduce material loss and achieve cost savings

High-precision equipment reduces component loss

The high-precision operation of automated production equipment can effectively reduce material loss in the production process. For example, automatic placement equipment can accurately place components in designated locations, reduce the possibility of material dislocation and displacement, and avoid component damage caused by incorrect operation. These technologies reduce material waste and help factories control production costs.

Real-time monitoring of material consumption and improved efficiency

Automated production lines are usually equipped with advanced monitoring systems that can track material consumption in real time. PCBA factories can use this data to adjust production plans in a timely manner to avoid unnecessary material consumption and inventory backlogs. Intelligent material management helps factories achieve "on-demand procurement", further reducing inventory and material costs.

4. Automation technology optimizes production quality and reduces defective product rates

Precisely control process parameters and improve product consistency

Automated equipment has strict process parameter control functions, so that variables such as temperature, time, and speed in the production process can be accurately maintained in an ideal state. For example, the reflow soldering machine can accurately control the soldering temperature to ensure the consistency and stability of each solder joint. Highly consistent product quality not only reduces the defective rate, but also saves rework costs caused by quality problems.

Reduce quality inspection costs and improve inspection efficiency

In PCBA processing, automated production lines can also integrate automatic inspection systems such as AOI (automatic optical inspection) or ICT (in-line testing) equipment to achieve rapid product inspection. Compared with manual quality inspection, the automated inspection system can detect defects in real time during the production process, greatly improve inspection efficiency, reduce labor costs for quality inspection, and reduce the risk of defective products entering the market.

5. Lower long-term maintenance costs and extended equipment life

Automated equipment is easier to maintain

Although the initial investment in automated equipment is high, its maintenance and operating costs are relatively low. Modern automated equipment is usually designed with self-monitoring and alarm functions, which can issue warnings before components are about to fail, reducing the risk of unexpected downtime. In the long run, automated equipment has a longer service life and lower maintenance costs, which helps PCBA factories achieve long-term cost savings.

Reduce equipment idleness and energy consumption

Automated production can reduce energy and resource waste by optimizing equipment utilization. For example, in the off-season or when production capacity demand is not high, the automated system can automatically adjust the operating frequency to avoid idle consumption of equipment, further reducing the energy cost of production, and bringing considerable long-term savings to the factory.

Summary

In the PCBA processing industry, automated production has become an effective means to improve cost-effectiveness. By reducing labor costs, improving production efficiency, reducing material loss, optimizing production quality and reducing maintenance costs, automated production helps PCBA factories significantly reduce overall production costs. In the fierce market competition, automation not only brings higher production efficiency to the factory, but also gives it stronger cost control capabilities, making the price of PCBA processing services more attractive. Choosing a PCBA factory with a high level of automation is an important guarantee for customers to obtain cost-effective products.

-

Delivery Service

-

Payment Options