- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

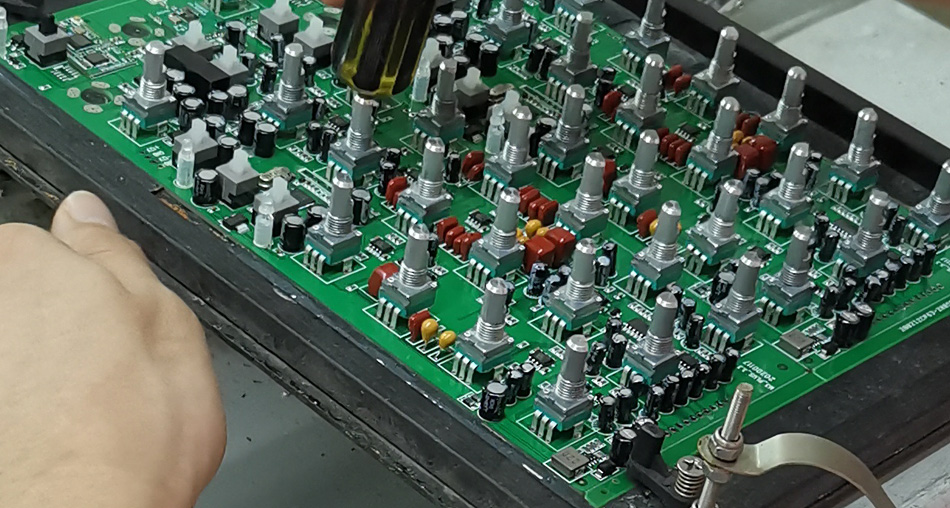

How to reduce the production cost of PCBA factories by optimizing the supply chain?

In the PCBA processing industry, the control of production costs is one of the key factors to enhance the competitiveness of enterprises. Supply chain management, as an important part of cost control, directly affects production efficiency, raw material procurement, inventory management, and delivery cycle. By optimizing the supply chain, PCBA factories can not only reduce production costs, but also improve overall operational efficiency. This article will explore how to reduce the production cost of PCBA factories by optimizing supply chain management.

1. Optimize raw material procurement

Centralized procurement reduces raw material costs

Raw material procurementis the largest part of the cost in PCBA processing. Through centralized procurement, PCBA factories can obtain discounts from suppliers with larger procurement volumes and reduce the procurement cost of single components. In addition, centralized procurement can also help factories establish long-term and stable cooperative relationships with suppliers, obtain better prices, payment terms and delivery times, and further reduce costs.

Choose a stable supplier to cooperate

Choosing a reliable supplier is crucial for PCBA factories. Stable suppliers can ensure the consistency of raw material quality and provide more competitive conditions when prices fluctuate. Establishing cooperative relationships with multiple suppliers and optimizing supplier management can enable PCBA factories to have stronger bargaining power when facing market price fluctuations, thereby controlling costs in the procurement process.

2. Accurate inventory management

Reduce inventory backlogs and reduce capital occupation

Excessive inventory will occupy a large amount of working capital and increase storage costs. In the PCBA processing process, reasonable inventory management can effectively reduce inventory backlogs and reduce unnecessary inventory capital occupation. By implementing a modern inventory management system, PCBA factories can monitor inventory in real time, accurately purchase raw materials according to production needs, and avoid cost waste caused by excess inventory.

Adopt JIT (Just-In-Time) production method

The JIT (Just-In-Time) production method requires on-demand procurement to reduce inventory backlogs. PCBA factories can coordinate with suppliers to ensure that raw materials are in place in a timely manner, avoid increased storage costs due to excessive inventory, and improve the smoothness and efficiency of the production process. The JIT production method can not only reduce inventory costs, but also reduce material expiration or damage caused by improper inventory management.

3. Optimize logistics and transportation management

Improve logistics efficiency and reduce transportation costs

Logistics costs account for a large proportion of PCBA processing. By optimizing logistics routes and improving transportation efficiency, PCBA factories can significantly reduce transportation costs. You can establish a long-term cooperative relationship with logistics companies to discuss more competitive transportation plans, or use container transportation and other methods to reduce the transportation cost of a single item. In addition, by choosing the right transportation method, the factory can also adjust the logistics plan in time according to production needs and reduce unnecessary transportation costs.

Reduce unnecessary transportation and warehousing links

In the supply chain, each additional transportation link will increase costs. By simplifying the transportation process and reducing the transit links, PCBA factories can effectively reduce the overall logistics costs. At the same time, choosing a more suitable warehousing method, such as shared warehousing or automated warehousing, can improve inventory management efficiency and reduce labor costs and warehousing costs.

4. Refined production scheduling

Optimize production plans and reduce production downtime

Production scheduling is a key link in the PCBA processing process. Optimizing production plans can reduce production downtime and improve production efficiency. Through accurate demand forecasting and production scheduling, PCBA factories can arrange production tasks at the appropriate time to avoid unnecessary waste caused by insufficient material supply or idle production lines. By reducing idle time in production, factories can not only increase output value, but also reduce the production cost of each unit product.

Application of flexible production lines

Flexible production lines can be flexibly adjusted according to production needs to adapt to the production requirements of different products. By introducing flexible production lines, PCBA factories can avoid downtime and re-debugging due to changes in production tasks, and reduce time costs and material waste caused by production adjustments. In addition, flexible production lines can also improve the utilization rate of production lines, make production plans more flexible, and further reduce production costs.

5. Improve the level of information management

Implement ERP system to improve supply chain transparency

The implementation of enterprise resource planning (ERP) system can improve the supply chain management level of PCBA factories, track material procurement, production progress and inventory in real time, ensure smooth information in the production process, and reduce wrong decisions caused by information lag. Through the ERP system, factories can adjust procurement plans and production arrangements in real time, improve overall production efficiency, and achieve cost control in all links of the supply chain.

Share information with suppliers to improve cooperation efficiency

A good cooperative relationship between PCBA factories and suppliers depends on information sharing. By sharing demand forecasts, inventory information and production plans with suppliers, factories and suppliers can better coordinate production and supply schedules, reduce uncertainties in the supply chain, ensure the smooth progress of production plans, and effectively reduce unnecessary costs in the production process.

6. Continuously optimize supply chain management

Regularly evaluate supply chain efficiency

Supply chain management is not a one-time process. PCBA factories need to regularly evaluate the efficiency of the supply chain and identify bottlenecks and deficiencies. Through regular evaluations, factories can promptly identify potential cost waste and inefficiency problems, and take corresponding optimization measures. Continuously improving supply chain management not only helps to reduce costs, but also improves the response speed and flexibility of the overall production process.

Innovate supply chain models and improve overall benefits

With the development of technology, PCBA factories can improve overall benefits through innovative supply chain models. For example, implementing blockchain technology to ensure the transparency of the supply chain, using artificial intelligence and big data analysis to optimize supply chain decisions, etc. Through these emerging technologies, factories can more accurately control production costs and improve the overall efficiency of the supply chain.

Summary

Optimizing supply chain management is an effective way for PCBA factories to reduce production costs. From raw material procurement, inventory management to logistics and production scheduling, optimizing every link of the supply chain helps to reduce unnecessary cost waste and improve production efficiency. Through refined supply chain management, PCBA factories can not only reduce production costs, but also improve product quality and timeliness of delivery, thereby gaining an advantage in the fierce market competition.

Send Inquiry

-

Delivery Service

-

Payment Options