- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

How PCBA factories can improve service quality through customer satisfaction management

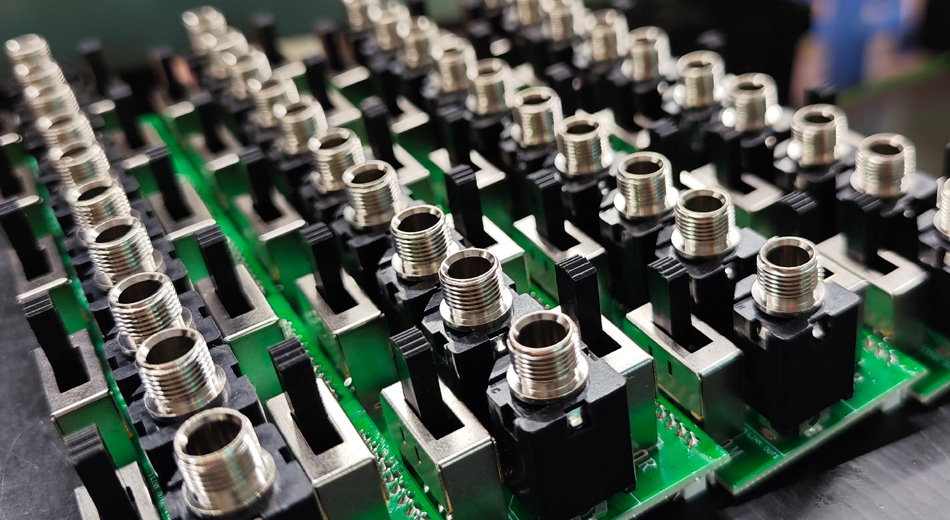

In the highly competitive PCBA processing industry, customer satisfaction has become a key factor in determining the long-term development and market competitiveness of factories. How to improve service quality and meet customer needs is a topic that every PCBA factory must pay attention to. Through effective customer satisfaction management, PCBA factories can not only enhance customer stickiness, but also improve service quality, thereby gaining a better market share. This article will explore how PCBA factories can improve service quality through customer satisfaction management.

1. The core goal of customer satisfaction management

Improve customer loyalty

During the PCBA processing process, customers often require high quality, high precision and timely delivery. Through customer satisfaction management, factories can better understand customer needs, pay attention to customer feedback, and continuously improve service quality. Customers with high satisfaction are more likely to become long-term partners, increase repeat orders, and thus improve customer loyalty. By establishing an effective customer satisfaction feedback mechanism, factories can quickly adjust production and service strategies to ensure that customers are always satisfied.

Improve service quality

By collecting customer feedback information, PCBA factories can accurately identify deficiencies in existing service processes and make targeted improvements. For example, customers may raise opinions on delivery cycles, technical support, after-sales service, etc. By regularly collecting and analyzing customer satisfaction data, factories can identify shortcomings in service quality, develop improvement plans, optimize production and service processes, and ultimately improve service quality.

2. Implementation steps for customer satisfaction management

Establish customer feedback channels

In order to effectively evaluate customer satisfaction, PCBA factories need to establish convenient customer feedback channels. Customers can express their opinions and suggestions on factories through online questionnaires, regular return visits, social media, etc. Through these channels, factories can understand customers' true feelings about product quality, delivery punctuality, technical support, etc., and adjust operating strategies in a timely manner. The collected feedback information can also help factories identify potential problems and avoid affecting customer experience.

Conduct satisfaction surveys regularly

PCBA factories should conduct customer satisfaction surveys regularly to understand customers' needs and expectations in different links. The survey content may include product quality, production efficiency, delivery punctuality, customer support, etc. Through a quantitative scoring system, factories can accurately evaluate customer satisfaction and find key issues in service. Regular satisfaction surveys not only help understand customers' current needs, but also identify long-standing potential problems, so as to make targeted improvements.

Analyze and process customer feedback

The collected customer feedback data needs to be systematically analyzed to find out the key factors that affect customer satisfaction. PCBA factories can identify bottlenecks in the production process or deficiencies in service by analyzing customer complaints, suggestions and comments. For example, customer feedback may indicate that delivery delays or product quality problems occur frequently. The factory can analyze the root causes of these problems through data analysis, optimize the process, and avoid recurrence of problems.

3. The role of customer satisfaction management in improving service quality

Improve product quality

Product quality in PCBA processing is one of the core elements that customers pay attention to. Through customer satisfaction management, the factory can accurately grasp customer expectations for product quality, and continuously improve production processes and improve product quality based on customer feedback. For example, the factory can optimize the production process by analyzing customer feedback on the reliability of electronic components, welding quality, etc., to ensure that each batch of products meets customer quality standards.

Improve delivery punctuality

Customer satisfaction is closely related to delivery time. Customers expect to receive high-quality products on time. Any delivery delay may lead to customer dissatisfaction and affect subsequent cooperation. Through customer satisfaction management, PCBA factories can promptly understand the problems in the delivery process and take measures to improve delivery efficiency. For example, factories can improve customer satisfaction by improving production scheduling, optimizing inventory management, and improving supply chain management capabilities to ensure that products are delivered on time.

Enhance after-sales service

After-sales service is an important part of customer satisfaction management. During the PCBA processing process, customers may encounter some technical problems or quality problems. Timely and effective after-sales service can greatly improve customer satisfaction. Through customer satisfaction management, factories can find deficiencies in after-sales service and improve service quality by training customer service teams, providing technical support, or adding special after-sales service channels to ensure that customer problems are quickly resolved.

4. Long-term benefits of customer satisfaction management

Establish good customer relationships

Through customer satisfaction management, PCBA factories can establish long-term and stable cooperative relationships with customers. Satisfied customers will not only continue to cooperate with the factory, but may also recommend the factory to other potential customers, bringing new business opportunities. Good customer relationships help factories increase their market share and consolidate their position in the industry.

Improve market competitiveness

The PCBA processing market is highly competitive, and customer needs are becoming increasingly diversified and personalized. By focusing on customer satisfaction, factories can better meet customer needs, improve service quality, and thus improve market competitiveness. Factories with high customer satisfaction are usually able to obtain more orders and stand out in the fierce market competition.

Conclusion

Through effective customer satisfaction management, PCBA factories can not only solve technical problems encountered by customers in the production and service process, but also continuously optimize service quality and improve production efficiency. By establishing a customer feedback mechanism, regularly surveying customer satisfaction, analyzing customer feedback, etc., factories can grasp customer needs in real time, adjust operating strategies, and ultimately improve customer satisfaction and promote the long-term development of the company.

Send Inquiry

-

Delivery Service

-

Payment Options