- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Environmental protection and compliance: the future development trend of PCBA factories

2025-06-20

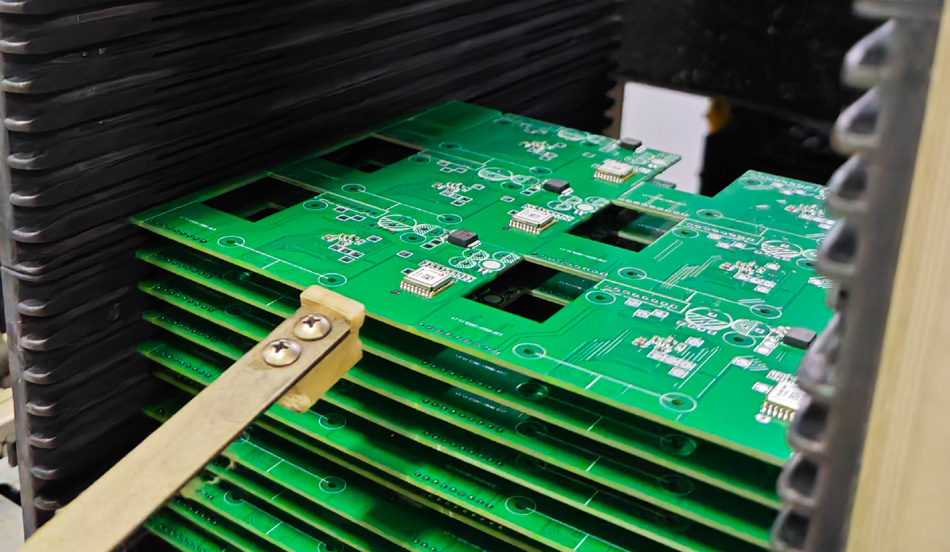

With the continuous improvement of global environmental awareness and the increasingly stringent environmental regulations of various countries, the future development direction of PCBA (printed circuit board assembly) factories is gradually moving towards green production and compliance requirements. How to ensure efficient production processes while meeting increasingly stringent environmental standards has become an important issue facing PCBA factories. This article will explore the environmental protection and compliance issues in the future development trend of PCBA factories and their impact on the long-term development of enterprises.

1. Increasingly stringent environmental regulations promote green production

With the continuous improvement of environmental regulations, governments around the world have put forward increasingly stringent requirements for the PCBA processing industry. Especially in the European Union, the United States and parts of Asia, environmental regulations (such as the RoHS Directive, the WEEE Directive, etc.) have become basic standards that PCBA factories must comply with. These regulations require PCBA factories to reduce the use of hazardous substances, use environmentally friendly materials, and ensure that the recycling and treatment of products meet environmental protection standards.

In the future, with the global emphasis on environmental protection, PCBA factories will pay more attention to environmentally friendly production, especially in the selection of materials, optimization of production processes and waste management. The use of lead-free solder, environmentally friendly PCB materials and efficient waste recycling technology will become the normal operation of PCBA factories.

2. Environmental certification becomes an industry standard

Environmental certification will become one of the important standards for future PCBA factories. Environmental certifications such as ISO 14001 environmental management system certification, ISO 9001 quality management system certification, and RoHS certification are not only a verification of the factory's environmental compliance capabilities, but also an important basis for customers to choose suppliers.

With the tightening of environmental regulations, PCBA factories with environmental certification will have stronger market competitiveness. Customers, especially multinational companies, pay more and more attention to whether suppliers meet environmental standards. Therefore, obtaining relevant certifications is not only a reflection of the company's fulfillment of social responsibility, but also can enhance its brand image and win more customers' trust and cooperation opportunities.

3. Improve energy management and reduce carbon emissions

Reducing carbon emissions is an important issue that PCBA factories must face in the process of achieving environmental compliance. A large amount of energy consumption is required during the PCBA processing process, including electricity and heat. Therefore, how to optimize energy use and improve energy management efficiency has become the key to the sustainable development of factories.

In the future, PCBA factories will introduce advanced energy management systems (EMS) to achieve intelligent monitoring and control of energy and reduce energy waste. For example, by introducing energy-saving equipment, optimizing production processes, and using renewable energy, factories can reduce carbon emissions while reducing energy consumption, in line with global environmental protection goals.

4. Innovate green production technology and promote technological upgrading

With the advancement of science and technology, green production technology will be more and more widely used in PCBA factories. Automated production lines, intelligent testing equipment, the use of harmless materials, 3D printing technology, etc. are all innovative technologies that PCBA factories may adopt in the process of environmental compliance in the future.

For example, automated production lines can reduce manual intervention, improve production efficiency, reduce human errors, and thus reduce scrap rates. Intelligent testing equipment can not only improve production quality, but also monitor energy use in the production process in real time, and promptly discover and correct problems of low energy efficiency. In addition, the use of environmentally friendly 3D printing technology can accelerate product development while reducing the waste of raw materials.

5. Improve waste management efficiency and promote circular economy

Waste management is an important part of PCBA factory environmental compliance. If the waste gas, waste water and solid waste generated during the production process are not effectively treated and recycled, it will not only burden the environment, but also may cause the company to face huge environmental fines.

In the future, PCBA factories will pay more attention to waste management, and maximize the utilization of waste by optimizing production processes and improving waste recovery rates. For example, advanced waste gas and wastewater treatment equipment can be used to reduce the emission of harmful substances; at the same time, waste circuit board materials, metals, plastics and other materials can be recycled to promote the development of the circular economy.

6. Digital management improves compliance

Digital management will be an important means for PCBA factories to achieve environmental protection and compliance in the future. Through the digital platform, the factory can monitor the energy use, waste emissions, equipment operation and other conditions in the production process in real time, so as to ensure that the environmental protection requirements in the production process are implemented.

Through big data analysis, PCBA factories can identify potential environmental problems and make adjustments in advance to avoid excessive emissions or waste of resources. In addition, digital management systems can also help companies better track and record compliance data to ensure that they can provide complete and transparent compliance reports when facing regulatory review.

Conclusion

With the tightening of environmental regulations and the increasing market demand for green production, the future development of PCBA factories will inevitably rely on the dual drive of environmental protection and compliance. By strengthening environmental management, improving energy efficiency, adopting green technology, and improving waste management, PCBA factories can not only reduce production costs, but also achieve long-term sustainable development. PCBA factories that meet environmental standards will occupy a favorable position in the future global market and promote the industry as a whole to move towards green and low-carbon.

-

Delivery Service

-

Payment Options