- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Labor cost issues and optimization strategies in PCBA processing

2025-04-28

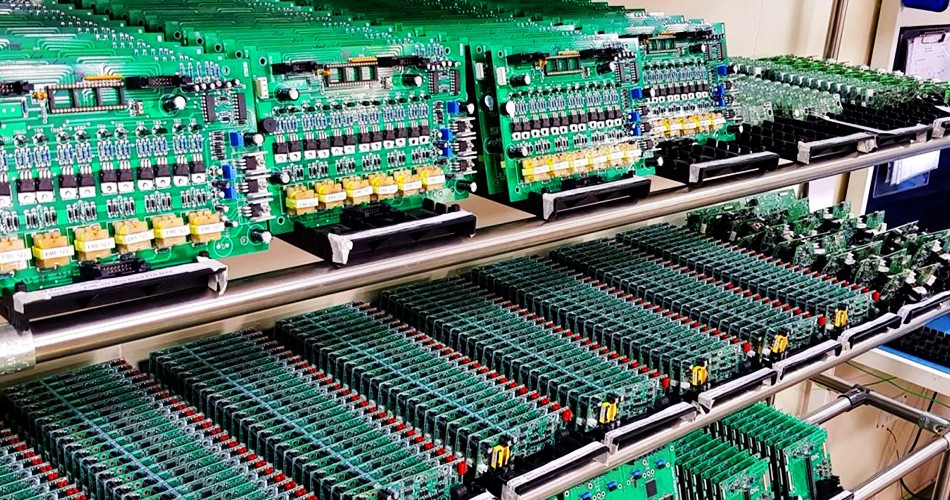

In the process of PCBA (Printed Circuit Board Assembly), labor cost is an important cost component. High labor costs will not only affect the profitability of enterprises, but also may affect the market competitiveness of products. Therefore, optimizing labor costs is the key to improving enterprise operating efficiency and reducing production costs. This article will explore the labor cost issues and optimization strategies in PCBA processing to help enterprises achieve more efficient cost management.

I. The main manifestations of labor cost issues

1. High labor costs: Due to the complex processing technology of PCBA, a large number of manual operations are required, such as mounting, soldering, and inspection of components. These operations usually involve a lot of manual labor, resulting in high labor costs.

2. Low production efficiency: The production efficiency of manual operation is usually lower than that of automated equipment. Manual operation is not only slow, but also prone to errors, affecting production efficiency and quality.

3. High skill requirements: PCBA processing requires high skills for workers and requires trained technical workers. The high salary level of highly skilled workers further increases labor costs.

4. High labor intensity: During the PCBA processing, the labor intensity of workers is high, which can easily lead to fatigue and reduced production efficiency. This not only affects the production speed, but may also increase the mobility of workers and increase recruitment and training costs.

II. Strategies for optimizing labor costs

1. Introducing automated equipment

Automated placement machines: Using automated placement machines to mount components can greatly improve the placement speed and accuracy and reduce the need for manual operation. Automated equipment can not only improve production efficiency, but also reduce quality problems caused by human factors.

Automated testing equipment: Introducing automated testing equipment (ATE) for electrical performance testing and functional testing can reduce the time and labor intensity of manual testing and improve the accuracy and consistency of testing.

2. Optimizing production processes

Process optimization: By optimizing the production process, reduce manual operations in the production process. For example, adopt more efficient soldering processes and materials, simplify production steps, and thus reduce dependence on manual labor.

Process standardization: Formulate standardized production processes and operating procedures to reduce the randomness and error rate of operations. Standardized processes can improve production efficiency and reduce training and management costs.

3. Improve workers’ skills and efficiency

Training and skill improvement: Regularly train workers to improve their skill level and operating efficiency. Technical training can not only improve production efficiency, but also reduce quality problems caused by improper operation.

Incentive mechanism: Establish an incentive mechanism to encourage workers to improve production efficiency and quality. For example, by setting production goals and reward mechanisms, workers’ enthusiasm and work passion can be stimulated.

4. Introduce advanced technology and equipment

Intelligent production system: Use intelligent production systems for production management, such as Internet of Things (IoT) technology and data analysis systems, to monitor the production process in real time, optimize resource allocation, and improve production efficiency.

Energy-saving and emission-reduction technology: Introduce energy-saving and emission-reduction technology to reduce energy consumption and waste generation in the production process, thereby reducing production costs. Energy-saving technology can not only reduce production costs, but also enhance the environmental image of the company.

5. Optimize labor distribution

Production line balance: Reasonably distribute labor and balance processes on the production line to ensure balanced loads in each process and avoid reduced production efficiency due to bottlenecks in a certain process.

Flexible employment: Flexibly adjust the number of employees and shifts according to changes in production demand. For example, add temporary workers or overtime during peak order periods, and reduce the number of workers during low order periods, thereby optimizing labor costs.

Conclusion

In PCBA processing, labor cost optimization is the key to improving production efficiency and reducing production costs. By introducing automated equipment, optimizing production processes, improving worker skills and efficiency, introducing advanced technology and equipment, and optimizing labor distribution, companies can effectively control and reduce labor costs. Looking to the future, companies should continue to pay attention to the best practices of labor cost management, and continue to explore and implement new optimization strategies to improve market competitiveness and achieve sustainable development.

-

Delivery Service

-

Payment Options