- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Root causes and improvement measures for delivery delays in PCBA processing

2025-04-22

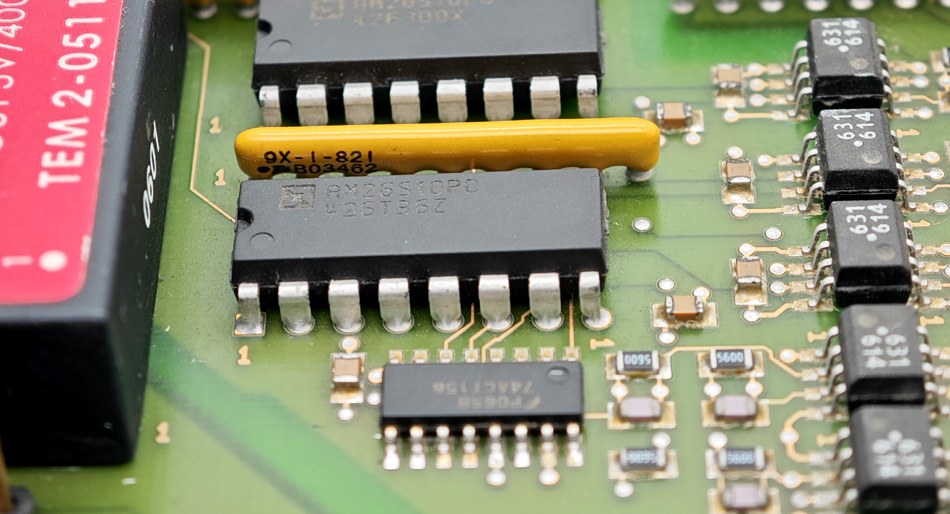

During the PCBA (Printed Circuit Board Assembly) processing process, delivery delays are a common problem that seriously affects the customer satisfaction and market competitiveness of enterprises. Delivery delays may not only lead to customer loss, but also bring additional costs and pressure to enterprises. Therefore, it is crucial for PCBA processing companies to understand the root causes of delivery delays and take effective improvement measures.

I. Root causes of delivery delays in PCBA processing

Delivery delays are usually caused by the combined effect of multiple factors. The following are the most common root causes in PCBA processing:

1. Insufficient material supply: Material shortage is one of the main reasons for delivery delays in PCBA processing. Since PCBA processing involves a variety of components and materials, if the supplier cannot deliver on time or there is insufficient inventory, the production schedule will be seriously affected, resulting in delivery delays.

2. Unreasonable production plan: The formulation of the production plan needs to consider multiple factors, including production capacity, material supply, process complexity, etc. If the plan is unreasonable, such as too tight scheduling or failure to consider emergencies, the production line is prone to bottlenecks, which in turn affects the overall production progress.

3. Equipment failure: PCBA processing requires a variety of complex equipment, such as placement machines, reflow soldering machines, etc. Once these devices fail, the repair and debugging process will take a lot of time, causing the production line to stagnate and eventually lead to delivery delays.

4. Quality control issues: During the PCBA processing process, if the product has quality problems, such as soldering defects or circuit board short circuits, it often needs to be reworked or remade. This not only increases production time, but may also affect the delivery time of the entire order.

5. Order changes: Customers' design changes or increased order quantities during the production process are also important factors leading to delivery delays. These changes usually require readjustment of production plans and bills of materials, resulting in extended delivery times.

II. Measures to improve delivery delays in PCBA processing

In order to reduce delivery delays in PCBA processing, companies can make improvements in the following aspects:

1. Strengthen supply chain management: Reduce dependence on a single supplier by establishing a diversified supply chain system. Companies should regularly evaluate suppliers' supply capabilities, establish a safety inventory of key materials, and ensure that production can continue when there are problems with material supply. In addition, keep close communication with suppliers, obtain material supply information in time, and prevent supply shortages in advance.

2. Optimize production plans: Enterprises should reasonably formulate production plans based on actual production capacity and order requirements. When scheduling production, leave enough time buffer to deal with emergencies. In addition, the use of advanced production management systems, such as ERP systems, can monitor production progress in real time, adjust production plans in time, and reduce production bottlenecks.

3. Regular equipment maintenance: In order to avoid production stagnation caused by equipment failure, enterprises should formulate strict equipment maintenance plans and regularly inspect and maintain key equipment. Through preventive maintenance, the probability of sudden equipment failure can be reduced and the continuous operation of the production line can be ensured.

4. Strengthen quality control: Strengthen quality inspection in all aspects of PCBA processing, especially in key process steps such as soldering and assembly. The introduction of advanced inspection equipment such as automatic optical inspection (AOI) and X-ray inspection (X-ray) can detect and correct quality problems in time and reduce the time loss of rework and remake.

5. Flexible response to order changes: When facing changes in customer orders, enterprises should maintain flexibility and efficient communication. By quickly adjusting the production plan and bill of materials, the impact of the change on the delivery time can be minimized. In addition, the change processing process can be negotiated with the customer to clarify the scope and conditions of the delivery time adjustment to avoid unnecessary disputes.

Conclusion

Delivery delay in PCBA processing is a complex issue, which is often caused by the combined effect of multiple factors. By strengthening supply chain management, optimizing production plans, regular equipment maintenance, strengthening quality control, and flexibly responding to order changes, companies can effectively reduce the occurrence of delivery delays and improve customer satisfaction and market competitiveness. The punctuality of delivery time is not only an important manifestation of the company's fulfillment of the contract, but also the key to the company's winning customer trust and long-term cooperation. Therefore, PCBA processing companies should continuously optimize internal processes and improve production efficiency to achieve stable delivery capabilities and high-quality customer service.

-

Delivery Service

-

Payment Options