- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

How to solve the cost overrun problem in PCBA processing

2025-04-16

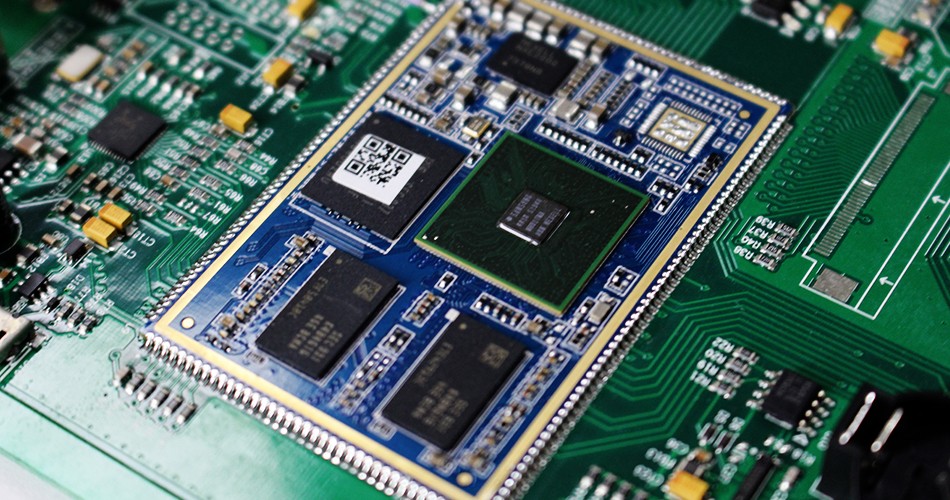

In PCBA processing (Printed Circuit Board Assembly), cost control is an important challenge faced by every enterprise. Since the links involved in PCBA processing are complex and changeable, from material procurement to production process to quality control, each link may cause cost overrun. If not managed, cost overrun will not only erode corporate profits, but also affect market competitiveness. This article will explore the common causes of cost overruns in PCBA processing and propose effective solutions.

1. Raw material procurement cost overrun

Problem analysis:

Raw material procurement is one of the main costs in PCBA processing. Due to market fluctuations, unstable supply chain or improper procurement plan, raw material prices may rise or procurement costs may increase. In addition, material shortages may also force companies to purchase from alternative suppliers at higher prices, further increasing cost pressure.

Solution strategy:

To control the cost of raw material procurement, companies should take the following measures:

Diversified supply chain: Establish a stable cooperative relationship with multiple suppliers, reduce dependence on a single supplier, and reduce procurement risks.

Long-term contract: Sign a long-term purchase contract with the supplier to lock in the price and reduce the impact of market fluctuations.

Optimize the purchase plan: Reduce the surplus or shortage of raw materials through accurate demand forecasting and inventory management, thereby reducing the purchase cost.

2. Inefficiency in the production process

Problem analysis:

During the production process, equipment failure, unstable process or improper operation will lead to low production efficiency and increase production costs. Especially in high-complexity and high-precision PCBA processing, the problem of inefficiency is particularly prominent, which may lead to extended production cycle and increased defective product rate.

Solution strategy:

In order to improve production efficiency, enterprises can take the following measures:

Equipment maintenance and upgrade: Regularly maintain and upgrade production equipment to ensure that the equipment is in the best condition and reduce the failure rate.

Optimize production process: Introduce advanced production process and automation equipment to improve production efficiency and product quality.

Implement lean production: Adopt lean production management methods to reduce waste and unnecessary links in production and improve the efficiency of production processes.

3. Rework costs caused by lax quality control

Problem analysis:

Inadequate quality control will lead to an increase in defective products in production, which will cause rework or scrapping. Rework not only requires additional labor and materials, but also delays production progress and increases overall production costs.

Solution strategy:

To reduce rework costs, companies should implement the following quality control measures:

Improve the quality management system: Establish a comprehensive quality management system to strictly monitor and inspect the production process, and promptly discover and correct quality problems.

Introduce automated testing equipment: Use advanced testing equipment such as automatic optical inspection (AOI) and X-ray inspection (AXI) to improve the accuracy and efficiency of testing.

Employee training: Strengthen training for production and quality management personnel, improve their skills and quality awareness, and reduce human errors.

4. Unreasonable production planning

Problem analysis:

Unreasonable production planning, such as delayed production planning, improper resource allocation, or scheduling errors, may lead to low production efficiency and increased costs. Especially when the order volume is large or the production cycle is short, unreasonable scheduling will lead to overtime and increase labor costs.

Solution strategy:

To optimize production plans, enterprises can take the following measures:

Introduce production management system: Use ERP (Enterprise Resource Planning) system and MES (Manufacturing Execution System) to optimize production plans and resource allocation, and realize real-time monitoring and adjustment.

Accurately predict demand: Based on historical data and market trends, make accurate demand forecasts and schedules to reduce overproduction or underproduction.

Flexibly adjust production schedules: According to order priority and production capacity, flexibly adjust production schedules to avoid production bottlenecks and resource waste.

Conclusion

To solve the cost overrun problem in PCBA processing, it is necessary to start from multiple aspects and comprehensively consider factors such as raw material procurement, production efficiency, quality control and production planning. By optimizing procurement strategies, improving production efficiency, strengthening quality management and reasonably arranging production plans, enterprises can effectively control costs, improve profitability, and maintain advantages in the highly competitive market. Continuous attention and improvement of these aspects of management will help enterprises achieve cost control goals and ensure the sustainable development of PCBA processing business.

-

Delivery Service

-

Payment Options