- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Dynamic system modeling in PCBA processing: from simulation to optimization

2025-04-01

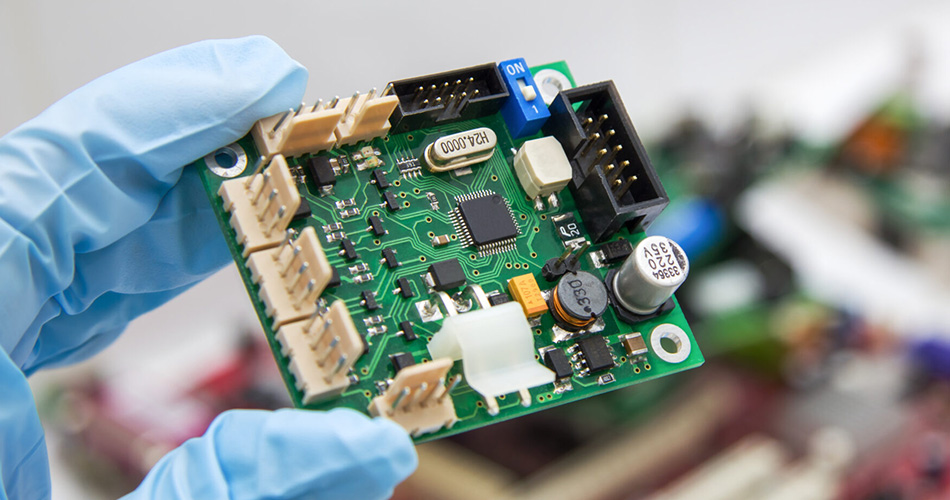

In the process of PCBA (Printed Circuit Board Assembly) processing, dynamic system modeling is a key technology used to simulate and optimize various factors in the production process. This modeling method can help engineers understand and predict system behavior, thereby improving production efficiency and product quality. This article will explore the application of dynamic system modeling in PCBA processing, including the process from simulation to optimization.

I. Overview of dynamic system modeling

1. Definition of dynamic system modeling

Dynamic system modeling refers to the use of mathematical models and computer simulation technology to model and analyze the dynamic behavior of the system. For PCBA processing, this modeling technology can be used to simulate various dynamic factors in the production process, such as temperature changes, signal transmission delays, and equipment performance fluctuations. Through dynamic modeling, engineers can predict the performance of the system under different conditions, so as to effectively optimize and improve it.

2. Technical advantages

Dynamic system modeling can significantly improve the transparency and controllability of the production process. Through accurate models and simulations, engineers can identify potential problems and bottlenecks, so as to take targeted measures to improve them. This not only helps to improve production efficiency, but also reduces production costs and reduces failure rates.

II. The process from simulation to optimization

1. Simulation stage

1.1 Data collection

Before dynamic system modeling, relevant data about the PCBA processing process needs to be collected. This data includes equipment performance, material properties, environmental conditions, etc. This information will serve as the basis for modeling and help engineers build accurate mathematical models.

1.2 Modeling and simulation

Based on the collected data, engineers can build dynamic system models. Common modeling methods include finite element analysis (FEA), computational fluid dynamics (CFD), and system dynamics models. Through computer simulation, the behavior of the system under different operating conditions can be simulated, including temperature changes, stress distribution, and signal transmission.

1.3 Verification and adjustment

After completing the preliminary model and simulation, verification is required to ensure the accuracy of the model. By comparing with actual production data, engineers can identify deviations in the model and make adjustments. This process helps to improve the reliability and prediction accuracy of the model.

2. Optimization stage

2.1 Goal setting

In the optimization stage, engineers need to clearly define the optimization goals, such as improving production efficiency, reducing scrap rates, or reducing production costs. Based on these goals, optimization strategies can be formulated, such as adjusting production parameters, improving equipment performance, or optimizing production processes.

2.2 Application of optimization algorithms

Optimization algorithms are applied to find the best production conditions and parameters. These algorithms include genetic algorithms, particle swarm optimization, and simulated annealing. By optimizing the dynamic system model, the goal can be maximized, thereby improving the overall production performance.

2.3 Implementation and monitoring

After determining the best optimization solution, it needs to be applied to actual production. The implementation process includes adjusting production equipment, updating production processes, and training operators. After implementation, the production process needs to be continuously monitored to ensure the effectiveness of the optimization measures, and necessary adjustments and improvements are made.

III. Challenges faced by dynamic system modeling

1. Model complexity

Dynamic system modeling involves complex mathematical and computational models. Building an accurate model requires a lot of expertise and experience, and processing a large amount of data and variables may increase the complexity of modeling.

2. Data accuracy

The accuracy of modeling depends on the quality of the input data. If the data is inaccurate or incomplete, the model's prediction results may be biased. Therefore, ensuring the accuracy and reliability of data is the key to dynamic system modeling.

3. Computing resources

Dynamic system modeling and simulation require a lot of computing resources and time. Complex models and high-precision simulations may require strong computing power and a long computing process, which challenges the computing resources and technical capabilities of enterprises.

Conclusion

The application of dynamic system modeling in PCBA processing provides a powerful tool for simulation and optimization of production processes. From data collection, modeling and simulation to optimization and implementation, this process can significantly improve production efficiency, reduce costs and improve product quality. Although dynamic system modeling faces challenges such as model complexity, data accuracy and computing resources, these problems can be effectively solved through reasonable strategies and technical applications to achieve continuous improvement and optimization of the production process.

-

Delivery Service

-

Payment Options