- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

How to choose the right PCBA processing software

2025-03-13

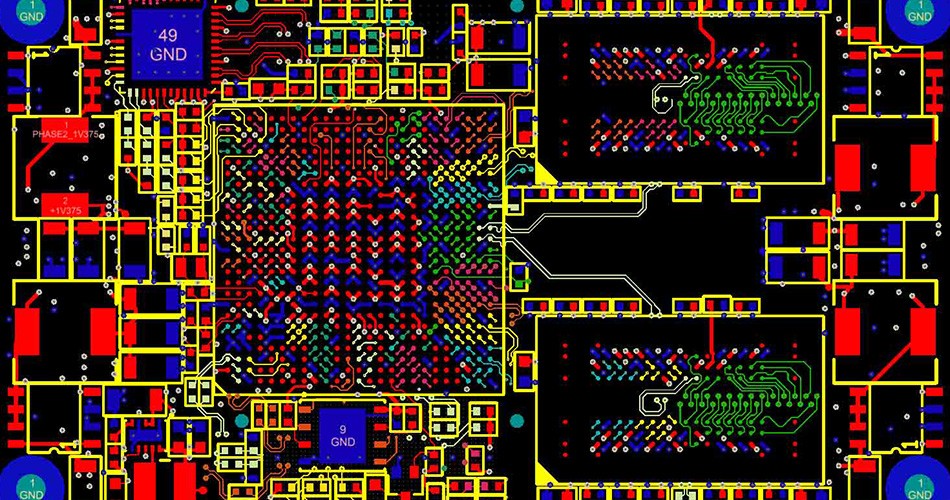

In PCBA (Printed Circuit Board Assembly) processing, choosing the right software tool is crucial to improving production efficiency and ensuring product quality. The right PCBA processing software can help optimize the design, testing and production processes, thereby achieving higher production efficiency and lower production costs. This article will explore how to choose the right PCBA processing software, including demand analysis, software functions, compatibility, user experience and technical support.

I. Demand Analysis

To choose the right PCBA processing software, you first need to clarify your needs. Different software tools differ in functions and scope of application. Understanding your specific needs can help you choose the most suitable tool.

1. Functional requirements: Determine which core functions are required, such as PCB design, component library management, automatic wiring, soldering simulation, etc. According to actual production needs and workflows, choose a comprehensive and suitable software tool.

2. Production scale: Consider the needs of production scale. If it is large-scale production, you may need more comprehensive software to support more complex design and production processes; if it is small-batch production, you may only need software that meets basic design and testing needs.

3. Budget constraints: Determine the scope of software selection based on the budget. Different software may have large differences in price, and you need to find a balance between functional requirements and budget when choosing.

II. Software functions and features

The functions and features of PCBA processing software are important considerations when choosing. Comprehensive software can provide higher production efficiency and better quality control.

1. Design function: Choose software with powerful design functions that can support various complex PCB design requirements, including multi-layer boards, HDI boards, etc. The software should have complete design tools, such as automatic wiring, design rule checking (DRC), etc.

2. Component library and management: Good component library management functions can improve design efficiency. Choosing software with rich component libraries and easy-to-manage library functions can save time in component selection and management.

3. Simulation and verification: Choosing software that supports functions such as soldering simulation, thermal analysis, and signal integrity analysis can detect problems in advance during the design stage and improve product stability and reliability.

4. Manufacturing support: Ensure that the software can generate production files that meet manufacturing standards, such as Gerber files, BOM (bill of materials), etc. These files are crucial for subsequent production and processing links.

III. Compatibility and Integration

The compatibility and integration capabilities of software are very important for improving production efficiency and reducing data transmission problems in work.

1. Compatibility with existing systems: Choose software that is compatible with existing design and production systems to avoid data conversion problems caused by system incompatibility. Ensure that the software can be seamlessly integrated into the existing production environment.

2. Data import and export: The software should support data import and export functions with other tools, such as CAD, CAM and other systems, to facilitate data exchange and collaboration between different stages and systems.

3. Integration with production equipment: If necessary, choose software that can be integrated with production equipment to achieve automated production processes and real-time data monitoring to improve production efficiency.

IV. User Experience and Support

Good user experience and technical support are essential for the long-term use of software. Choosing software that is easy to operate and fully supported can greatly improve work efficiency and satisfaction.

1. User interface: Choose software with a user-friendly interface and easy operation to reduce learning costs and operating difficulties. Software with an intuitive user interface can improve work efficiency and reduce errors.

2. Training and support: Choose a software vendor that provides comprehensive training and technical support. Good technical support can help solve problems in use and ensure the normal operation and efficient use of the software.

3. Community and resources: Choosing software with active user communities and rich resources can gain more experience and skills and solve problems encountered during use.

V. Software evaluation and trial

Before making a final decision, evaluating and trying out the software can help you better understand the actual performance and applicability of the software.

1. Trial version: Use the trial or demo version of the software to test its functions and performance to ensure that it meets actual needs. During the trial, pay attention to the stability of the software, whether the functions are complete, and whether it is easy to operate.

2. User evaluation: Check other users' evaluations and feedback to understand the performance and problems of the software in actual use. User evaluation can provide more realistic information about the use experience.

3. Technical documentation and support: Read the technical documentation and user manual of the software to understand its functional details and operation guide. At the same time, evaluate the technical support and service quality provided by the supplier.

Summary

Choosing the right PCBA processing software requires comprehensive consideration of multiple aspects such as demand analysis, software functions, compatibility, user experience, and technical support. By clarifying requirements, evaluating functions, ensuring compatibility, paying attention to user experience, and conducting trial evaluations, companies can find the most suitable software tools to improve production efficiency and product quality and achieve the best results in PCBA processing.

-

Delivery Service

-

Payment Options