- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

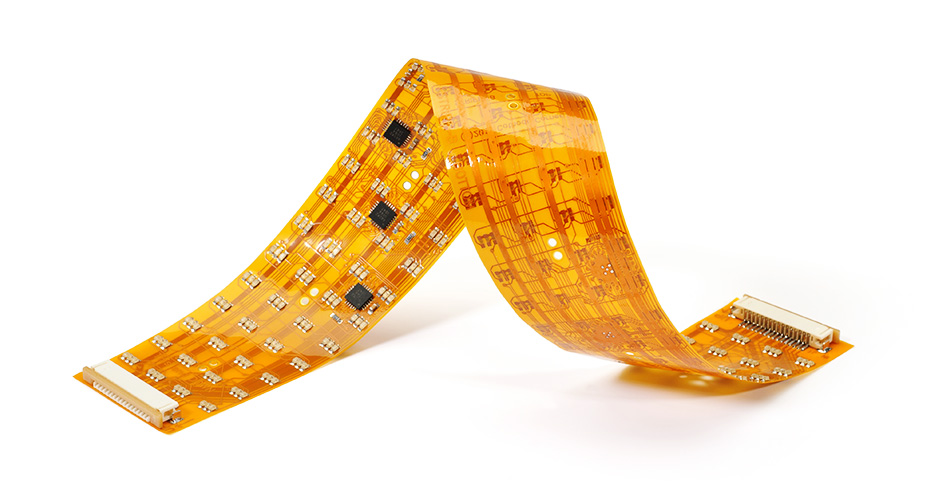

Flexible Circuit Board Technology in PCBA Processing

2025-03-11

In modern electronic products, flexible circuit board technology is widely used due to its unique advantages. Flexible circuit board (FPC) is thin, bendable and has high-density integration, which makes it play an important role in various complex and compact electronic devices. This article will explore how to use flexible circuit board technology to improve product performance and manufacturing efficiency in PCBA (Printed Circuit Board Assembly) processing.

I. Overview of Flexible Circuit Board Technology

Flexible circuit board technology refers to the use of flexible substrates in the manufacture of circuit boards to achieve the bending, folding and curling of circuit boards. This technology allows circuit boards to achieve more functions in a limited space and adapt to complex three-dimensional spatial structures. Compared with traditional rigid circuit boards, flexible circuit boards have many unique advantages in design and application.

1. Flexible substrate: Flexible circuit boards usually use flexible materials such as polyimide (PI) or polyester (PET) as substrates. These materials have excellent flexibility and high temperature resistance, allowing the circuit board to work normally under folding and bending.

2. High-density integration: Flexible circuit boards can achieve higher circuit density and support smaller electronic product designs. Through high-density circuit design, more functions can be integrated in a limited space to meet the needs of modern electronic products for miniaturization and high integration.

II. Application fields of flexible circuit boards

Flexible circuit board technology is widely used in multiple industries and application fields, especially in electronic devices that need to save space or require complex shapes.

1. Consumer electronics: Flexible circuit board technology is widely used in consumer electronic products such as smartphones, tablets and wearable devices. These products usually require high-density integration and compact design, and flexible circuit boards can effectively solve these design problems.

2. Automotive electronics: Flexible circuit boards in automotive electronic systems can be used for components such as dashboards, control panels and sensors. These components usually require high durability and vibration resistance, and flexible circuit board technology can meet these needs.

3. Medical equipment: In medical equipment, such as pacemakers, monitoring equipment and endoscopes, the use of flexible circuit boards can achieve complex electronic functions while adapting to the dynamic shape and small space of the equipment.

III. Advantages of flexible circuit boards in PCBA processing

The use of flexible circuit board technology in PCBA processing has many advantages, which can significantly improve the overall performance and manufacturing efficiency of the product.

1. Save space: Flexible circuit boards can achieve higher integration in design, reduce the layout space of components, and thus save the volume of the product. For electronic products that require compact design, flexible circuit boards can effectively improve space utilization.

2. Improve reliability: Flexible circuit boards have excellent impact resistance and vibration resistance. Due to their flexible characteristics, they can better adapt to mechanical stress and vibration, reduce failures caused by cracking or desoldering of traditional rigid circuit boards, and improve the overall reliability of products.

3. Simplify assembly: The use of flexible circuit boards can reduce the number of connectors and soldering points and simplify the assembly process of products. This can not only improve production efficiency, but also reduce assembly costs.

4. Improve design flexibility: Flexible circuit boards can be routed in complex three-dimensional spaces, supporting more complex circuit designs and functional integration. This provides designers with greater flexibility to achieve more functions in a smaller space.

IV. Challenges of Flexible Circuit Board Technology

Despite the many advantages of flexible circuit board technology, there are still some challenges in PCBA processing. Understanding these challenges and taking corresponding measures is the key to ensure the successful application of technology.

1. Cost issues: The manufacturing cost of flexible circuit boards is relatively high, especially when it comes to high precision and complex designs. Cost control is required in the design stage to ensure that the project is completed within the budget.

2. Processing difficulty: Flexible circuit boards are difficult to process, especially in folding and bending parts. High-precision manufacturing processes and equipment are required to ensure that no defects occur during the processing.

3. Long-term reliability: Although flexible circuit boards perform well in the short term, their reliability and stability in long-term use still need attention. Rigorous testing and verification are required to ensure their performance and durability in long-term use.

Conclusion

Flexible circuit board technology has significant advantages in PCBA processing, including space saving, improved reliability, simplified assembly and enhanced design flexibility. Despite some challenges, through reasonable design and processing technology, its advantages can be fully utilized to meet the needs of modern electronic products for high integration and compact design. With the continuous advancement of technology, flexible circuit boards will become an indispensable and important technology in PCBA processing, providing strong support for the innovation and development of electronic products.

-

Delivery Service

-

Payment Options