- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

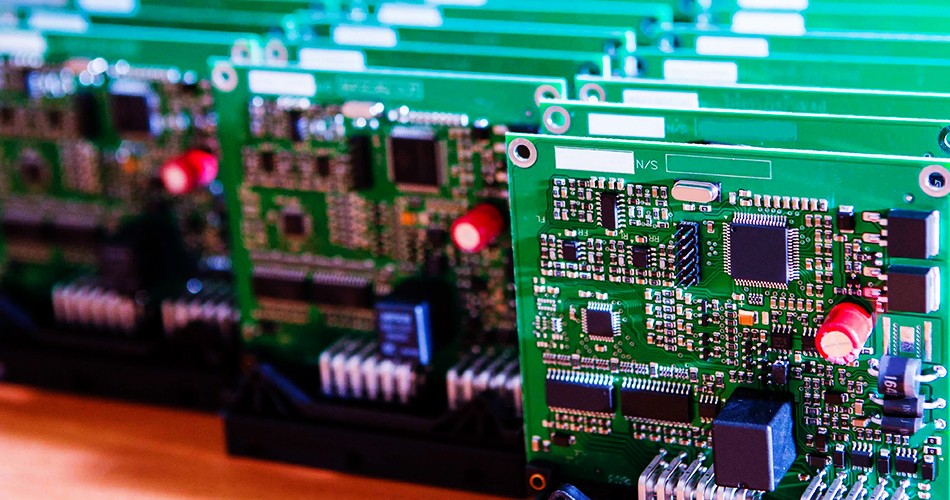

Environmentally friendly technology in PCBA processing

2025-02-28

With the improvement of environmental awareness and strict regulations, the PCBA (Printed Circuit Board Assembly) processing industry is gradually turning to environmentally friendly production technology. The use of environmentally friendly technology can not only reduce the negative impact on the environment, but also enhance the social responsibility of enterprises. This article will explore several key environmentally friendly technologies in PCBA processing to help enterprises in the industry achieve sustainable development.

1. Lead-free soldering technology

Traditional PCBA processing uses lead-containing soldering materials, which may pollute the environment during use and disposal. To solve this problem, many companies have turned to lead-free soldering technology. Lead-free soldering materials mainly include tin-silver-copper alloy (SAC), which not only has superior performance, but also has no long-term impact on the environment. The use of lead-free soldering technology can effectively reduce the emission of harmful substances and meet international environmental standards such as RoHS (Restriction of the Use of Certain Hazardous Substances Directive).

2. Use of green chemicals

In the process of PCBA processing, the use of chemicals is inevitable. However, traditional chemicals often contain ingredients that are harmful to the environment. For this reason, more and more companies are starting to use green chemicals. These chemicals not only reduce the use of harmful substances, but also improve safety during the production process. Green cleaning agents and deflux agents are common environmentally friendly choices that can effectively remove dirt and residues from circuit boards while reducing the impact on the environment.

3. Efficient waste management

Waste management is a vital part of PCBA processing. Companies need to effectively handle solid and liquid waste during the production process. By implementing efficient waste sorting and recycling systems, companies can reduce waste generation and disposal costs. Many companies have adopted advanced waste treatment technologies, such as waste incineration and resource utilization, to convert waste into reusable resources and reduce dependence on landfills.

4. Low-energy production

Reducing energy consumption is the key to achieving environmental protection goals. PCBA processing companies can reduce energy consumption by optimizing production processes and using energy-saving equipment. For example, using efficient power supply systems, optimizing the thermal efficiency of heating furnaces, and using energy-saving lighting systems are all effective measures to reduce energy consumption. Reducing energy consumption can not only reduce production costs, but also reduce greenhouse gas emissions.

5. Green packaging materials

The environmental friendliness of packaging materials should not be ignored. Traditional packaging materials such as foam plastics and plastic bags have placed a great burden on the environment. In response to this problem, many PCBA processing companies choose to use degradable or recyclable packaging materials. Paper packaging, renewable plastics, and biodegradable materials are all ideal choices for environmentally friendly packaging. This can not only reduce the generation of packaging waste, but also enhance the environmental image of the company.

6. Intelligent production technology

Intelligent production technology can help PCBA processing companies achieve a more efficient and environmentally friendly production process. Through data analysis and artificial intelligence (AI), companies can monitor the operating status of the production line in real time, optimize the production process, and reduce resource waste. Intelligent production systems can also predict and prevent potential equipment failures, further improve production efficiency, reduce resource waste and environmental impact.

Summary

Introducing environmentally friendly technologies in PCBA processing not only helps to reduce negative impacts on the environment, but also enhances the company's social responsibility and market competitiveness. From lead-free soldering, green chemical use, waste management to low-energy production, green packaging materials and intelligent production technology, these environmental protection measures are the key to achieving sustainable development. Companies should actively adopt these technologies to contribute to protecting the environment and promoting green manufacturing.

-

Delivery Service

-

Payment Options