- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Production line management in PCBA processing

2025-02-26

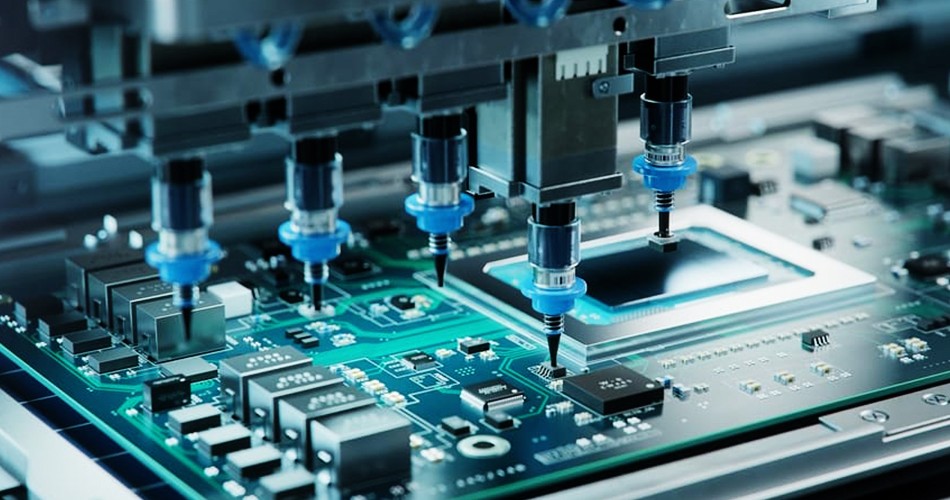

In PCBA (Printed Circuit Board Assembly) processing, production line management is a key link to ensure production efficiency, product quality and cost control. Effective production line management can not only improve production efficiency, but also reduce unnecessary waste and problems in production. This article will explore production line management in PCBA processing, including production line planning, process optimization, personnel management and quality control.

I. Production line planning

Production line planning is the basis for efficient production in PCBA processing. Reasonable production line planning can improve production efficiency, reduce waste, and optimize resource allocation.

1. Production line layout

Layout design: When designing the production line layout, it is necessary to make reasonable arrangements according to the requirements of the production process and the production process. The production line should minimize the material handling distance as much as possible to ensure smooth process connection. When designing the layout, the layout of the equipment, the flow of materials and the convenience of personnel operation should be considered.

Workstation configuration: The production line is divided into several workstations with clear functions, and each workstation is responsible for a specific process. Reasonable configuration of workstations can improve production efficiency, reduce waiting time between processes, and ensure quality control at each link.

2. Equipment selection and maintenance

Equipment selection: Select appropriate equipment according to production needs, such as placement machines, reflow machines, and testing equipment. The performance of the equipment directly affects production efficiency and product quality, so it is crucial to select high-quality equipment that is suitable for production needs.

Equipment maintenance: Regularly maintain and calibrate the equipment to ensure the normal operation of the equipment. Regular maintenance can reduce equipment failures, reduce downtime, and ensure the stability and production efficiency of the production line.

II. Process optimization

Process optimization is an important means to improve the efficiency of PCBA processing production lines. By optimizing the production process, the overall efficiency and product quality of the production line can be improved.

1. Process optimization

Process flow design: Analyze the production process in detail to identify and eliminate bottlenecks. Optimizing the process flow can reduce waiting time and unnecessary operations in the process and improve the smoothness of the production line.

Application of automation technology: The introduction of automation technology, such as automatic placement machines and automatic detection systems, can improve production efficiency and reduce errors caused by manual operations. Automation technology can also improve the consistency and stability of the production line.

2. Material Management

Material Management System: Implement an effective material management system to ensure timely supply and accurate allocation of materials. Use advanced material management software to track material inventory and usage to reduce the risk of material shortage or surplus.

Supply Chain Optimization: Optimize supply chain management to ensure timely delivery of raw materials and components. Establish a good cooperative relationship with suppliers to ensure the quality and delivery time of materials to support the smooth operation of the production line.

III. Personnel Management

Personnel management is a key factor in ensuring the efficient operation of PCBA processing production lines. Effective personnel management can improve employee work efficiency and the overall performance of the production line.

1. Employee Training

Training Plan: Develop a detailed employee training plan, including operating skills, safety regulations and quality standards. Regular training can improve employee skills and reduce operating errors and production defects.

Skill Improvement: Provide continuous skill improvement opportunities and encourage employees to learn new technologies and methods. By continuously improving employee skills, they can adapt to changes in production processes and technological advances.

2. Work Arrangement and Incentives

Work Arrangement: Rationally arrange employee work shifts and tasks according to production needs to ensure the efficient operation of the production line. Reasonable work arrangements can avoid overwork and improve employees' work enthusiasm and efficiency.

Incentives: Implement effective incentives, such as performance rewards and promotion opportunities, to motivate employees' work enthusiasm and creativity. Incentives can improve employees' job satisfaction and promote the healthy operation of the production line.

IV. Quality Control

Quality control is an important link in the management of PCBA processing production lines. Through effective quality control measures, it can ensure that the quality of products meets the standards and reduce defects and rework.

1. Quality inspection

Inspection equipment: Equipped with advanced quality inspection equipment, such as automatic optical inspection (AOI) and X-ray inspection systems, each link in the production process is comprehensively inspected. Through automated inspection, the accuracy and efficiency of inspection can be improved.

Quality standards: Establish clear quality standards and inspection processes to ensure that each production link meets quality requirements. Regularly conduct quality reviews and improvements to improve the quality level of the production line.

2. Feedback and improvement

Feedback mechanism: Establish an effective quality feedback mechanism to collect quality data and problem feedback during the production process. By analyzing quality data, timely discover and solve problems in production.

Continuous improvement: Based on quality feedback and test results, continuously improve production processes and procedures. Implement improvement measures to optimize the operation and management of the production line, and improve overall production efficiency and product quality.

Summary

In PCBA processing, production line management involves multiple aspects such as production line planning, process optimization, personnel management and quality control. By rationally planning the production line layout, optimizing the production process, effectively managing personnel and strictly controlling quality, production efficiency can be improved, production costs can be reduced, and high product quality can be ensured. With the development of technology and changes in market demand, continuous improvement of production line management strategies will help companies maintain their advantages in the fierce market competition.

-

Delivery Service

-

Payment Options