- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

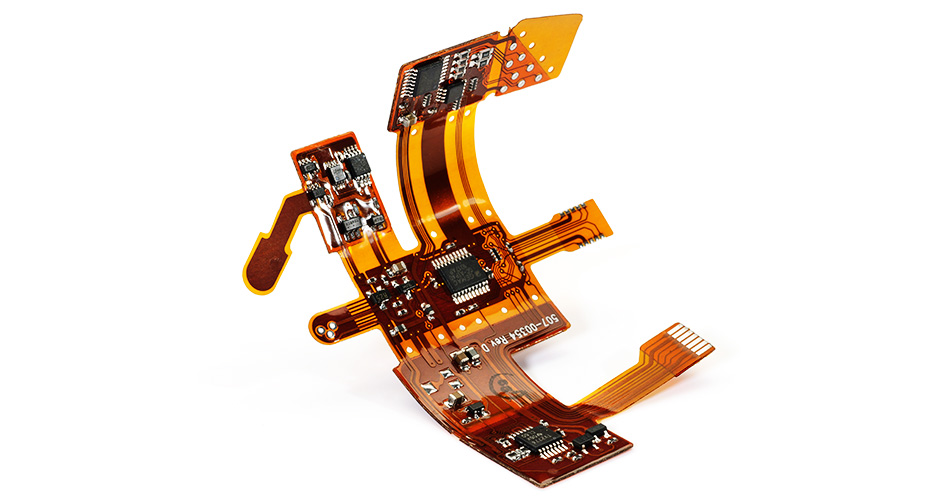

Design of flexible production line in PCBA processing

2025-02-12

With the rapid iteration of electronic products and the diversification of market demand, PCBA (Printed Circuit Board Assembly) processing companies are facing more and more challenges of small-batch and multi-variety production. In this context, flexible production line design has become an important strategy in PCBA processing. Flexible production lines can not only respond quickly to market changes, but also improve production efficiency and reduce production costs. This article will explore the key elements and advantages of flexible production line design in PCBA processing.

I. The concept and importance of flexible production lines

Flexible production lines refer to production line designs that can be quickly adjusted and switched according to different product or process requirements without affecting production efficiency. Compared with traditional fixed production lines, flexible production lines have higher adaptability and flexibility, and can meet the needs of small-batch and multi-variety production in PCBA processing.

1. Quick response to market demand

In PCBA processing, the rapid changes in market demand require companies to have the ability to flexibly adjust production lines. Flexible production line design enables companies to produce PCBA products of different specifications and types without large-scale equipment modification or re-layout, thereby quickly responding to customer needs and shortening product time to market.

2. Improve production efficiency

Through reasonable flexible production line design, enterprises can complete the assembly of multiple products on the same production line, greatly reducing line change time and downtime. At the same time, flexible production lines can also optimize resource allocation, improve equipment utilization and production efficiency.

II. Key elements of flexible production line design

In PCBA processing, successful flexible production line design needs to comprehensively consider multiple factors, such as the versatility of equipment, standardization of process flow and improvement of automation level.

1. Versatility of equipment

The versatility of equipment in flexible production lines is the basis for flexible adjustment of production lines. Enterprises should give priority to production equipment with multi-functional and modular design. For example, placement machines and reflow soldering equipment that support multiple packaging forms and soldering processes can be selected to quickly switch between different products.

2. Standardization of process flow

In order to improve the efficiency of flexible production lines, enterprises should standardize the design of key process flows in PCBA processing. By formulating unified process standards and operating specifications, production fluctuations and quality problems caused by process adjustments can be reduced. At the same time, standardized process flows can also improve the reproducibility of production lines and help the rapid introduction of new products.

3. Improvement of automation level

Automation is an important part of flexible production line design. By introducing intelligent equipment and information management systems, enterprises can realize automation and intelligence of the production process, reduce manual intervention, and improve the flexibility and response speed of the production line. For example, the use of automatic material conveying systems and intelligent warehousing systems can achieve rapid switching and precise distribution of materials, thereby reducing line change time.

III. Application examples of flexible production lines

In the PCBA processing industry, there have been many successful examples of flexible production line applications. These production lines have performed well in improving production efficiency, reducing costs, and improving product quality.

1. Multi-variety small batch production

Flexible production lines play an important role in multi-variety small batch production. For example, when producing various specifications of smart device circuit boards, flexible production lines can quickly adjust equipment parameters according to order requirements to complete the production tasks of different products, avoiding the inefficiency of traditional production lines caused by frequent line changes.

2. Rapid new product introduction

Another typical application of flexible production lines is the rapid introduction of new products. In PCBA processing companies, flexible production lines can quickly adapt to the production needs of new products through standardized processes and modular equipment, shorten the time from research and development to mass production of new products, and help companies seize market opportunities.

Summary

In PCBA processing, flexible production line design is not only an important strategy to cope with market changes, but also a key means to enhance corporate competitiveness. Through the improvement of equipment versatility, process standardization and automation level, flexible production lines can achieve rapid switching and efficient operation of production, which will win advantages for companies in the fierce market competition. With the continuous changes in market demand, flexible production line design will play an increasingly important role in PCBA processing, driving companies to develop in a more flexible and efficient direction.

-

Delivery Service

-

Payment Options