- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

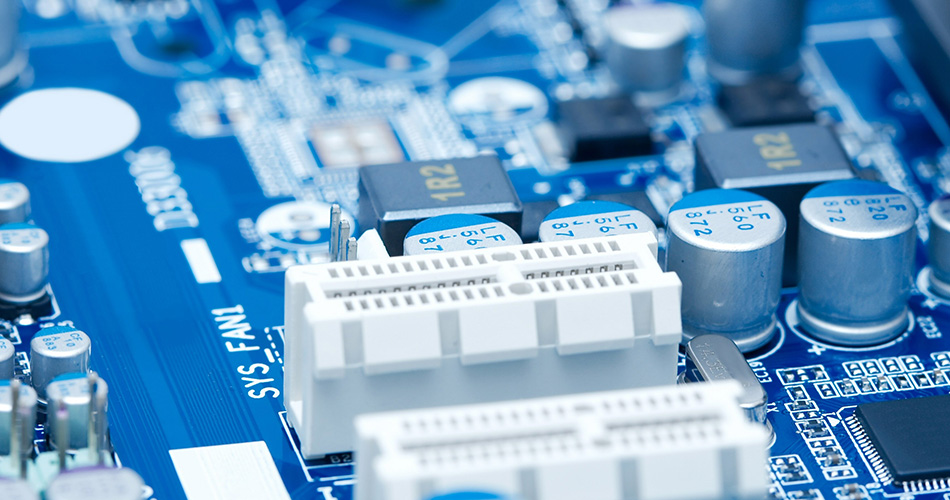

How to improve product appearance through PCBA processing

2025-01-25

1. Optimize circuit board design

Circuit board design is the starting point for PCBA processing and has an important impact on product appearance. Optimizing circuit board design can significantly improve product appearance. Specific measures include:

1. Reasonable layout: When designing a circuit board, the components should be laid out reasonably to avoid too dense or uneven components and ensure that the circuit board is clean and beautiful.

2. Wiring design: Use reasonable wiring design to avoid overly complex and crossing lines and keep the circuit board clean and beautiful.

3. Choose the appropriate color: The color of the circuit board is also an important factor affecting the appearance of the product. Common circuit board colors include green, blue, black, etc. Choosing the appropriate color can enhance the visual effect of the product.

2. Select high-quality components

The quality and appearance of components directly affect the appearance of the final product. In PCBA processing, selecting high-quality components is an important measure to improve the appearance of the product:

1. Brand components: Choosing components from well-known brands will not only ensure performance and reliability, but also enhance the overall appearance of the product.

2. Consistency: Ensure that components of the same batch are consistent in appearance to avoid unsightly products due to differences in appearance.

3. Fine processing: Choose finely processed components to avoid problems such as rough and uneven surfaces.

3. Optimize soldering process

The soldering process is a key link in PCBA processing, which directly affects the appearance quality of the circuit board. Optimizing the soldering process can significantly improve the appearance of the product. Specific measures include:

1. Choose the appropriate soldering method: According to the characteristics of the components and circuit board, choose the appropriate soldering method, such as reflow soldering, wave soldering, etc., to ensure the soldering quality.

2. Control the soldering temperature: If the soldering temperature is too high or too low, it will affect the soldering quality. The soldering temperature must be strictly controlled to ensure that the solder joints are beautiful and strong.

3. Use high-quality solder: Choose high-quality solder to avoid problems such as oxidation and cracking of solder joints and improve the soldering effect.

4. Surface treatment technology

Surface treatment technology is an important means to improve the appearance of PCBA processed products. Appropriate surface treatment technology can make circuit boards more attractive:

1. Spray tin: Spray tin technology can make the surface of the pad bright and smooth, improving the aesthetics of the circuit board.

2. Gold plating: Gold plating technology not only improves the conductivity of the circuit board, but also improves its corrosion resistance and aesthetics.

3. Immersion silver/immersion tin: Immersion silver and immersion tin technology can make the surface of the circuit board smooth and smooth, improving the appearance.

5. Strict quality control

In PCBA processing, strict quality control is an important guarantee to ensure the appearance quality of the product:

1. Incoming material inspection: All components and materials entering the factory are strictly inspected to ensure that they meet quality standards.

2. Process inspection: During the production process, technologies such as automatic optical inspection (AOI) are used to inspect each process to detect and correct problems in a timely manner.

3. Finished product inspection: Conduct appearance inspection after product assembly is completed to ensure that each product meets appearance quality requirements.

in conclusion

By optimizing the circuit board design, selecting high-quality components, optimizing the soldering process, adopting appropriate surface treatment technology and strict quality control, the appearance quality of the product can be significantly improved during the PCBA processing process. This can not only meet consumers' high requirements for product appearance, but also enhance the market competitiveness of products. PCBA processing companies should continue to explore and apply new technologies and methods, continue to improve the appearance and overall quality of products, and provide customers with better products.

-

Delivery Service

-

Payment Options