- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

How to improve product reliability through PCBA processing

2025-01-13

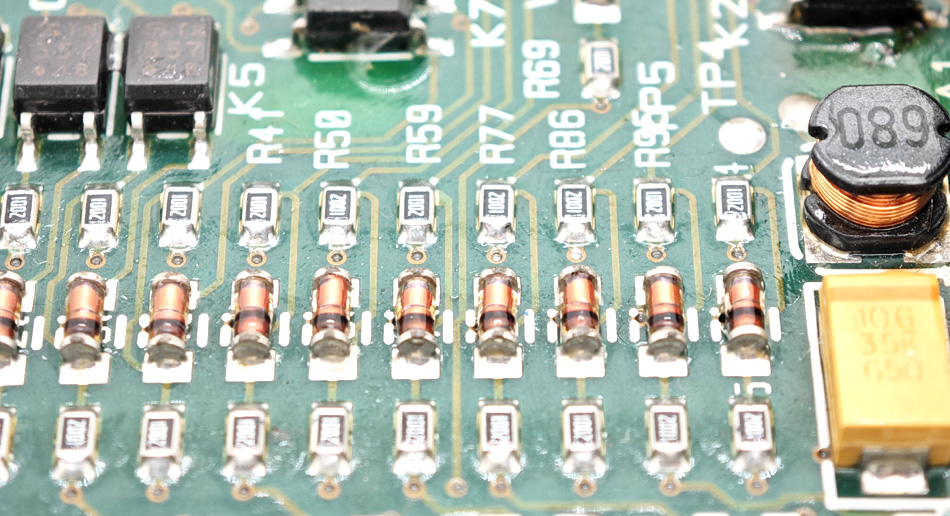

In modern electronic products, PCBA (Printed Circuit Board Assembly) processing is a crucial link, which directly affects the performance and reliability of the final product. In order to improve the reliability of the product, it is necessary to carry out refined management and optimization at each stage of PCBA processing. This article will explore how to improve the reliability of the product in PCBA processing through methods such as design optimization, material selection, process control and quality inspection.

Design for manufacturability

Optimization in the design stage is the starting point for improving product reliability. By considering the feasibility of the manufacturing process, possible problems in the production process can be reduced.

Simplified design: Simplify circuit design and reduce complexity, such as reducing excessive traces and pads, optimizing component layout, and reducing production difficulty.

Thermal management design: Rationally design the heat dissipation path and the location of the heat sink to avoid performance degradation or failure caused by overheating of components.

Implementation strategy: Conduct a detailed design review in the design stage to ensure the manufacturability and reliability of the design and avoid potential manufacturing and use problems.

High-quality materials

Selecting high-quality raw materials is crucial to improving product reliability. Using high-quality materials can effectively avoid performance problems or failures caused by material problems.

PCB substrate: Select PCB substrate that meets the requirements, such as FR-4, CEM-1, etc., to ensure its electrical performance and thermal stability.

soldering materials: Use high-quality solder alloys and flux to ensure the strength and reliability of solder joints.

Implementation strategy: Select high-quality materials that meet industry standards, conduct material verification and performance testing, and ensure that they are suitable for the expected application environment.

Strict process control

Controlling the production process is the key to improving the reliability of PCBA processing. Through standardized process control, ensure that every production link meets the standards.

soldering process: Optimize soldering parameters, control soldering temperature, time and solder amount, and avoid solder joint defects such as cold solder joints.

Automated equipment: Use automated equipment for soldering and assembly to improve soldering consistency and accuracy and reduce human errors.

Implementation strategy: Establish standardized process flow and operating procedures, strictly control and monitor the production process, and ensure that each link meets quality standards.

Multi-level quality inspection

Implementing multi-level quality inspection can effectively discover and solve problems in production and improve product reliability.

Visual inspection: Visual inspection of solder joints, component positions and appearance to detect obvious defects.

Functional testing: Functional testing is performed after production to verify whether the circuit board is working properly according to the design requirements.

Automated optical inspection (AOI): Use AOI equipment for automated inspection to quickly identify problems such as solder joint defects and component deviations.

Implementation strategy: Implement comprehensive quality inspection during the production process, including visual inspection, functional testing and AOI inspection, to promptly detect and handle defects and improve product reliability.

Environmental adaptability test

Environmental adaptability test can evaluate the reliability of products under different environmental conditions and ensure their stability in actual applications.

Temperature test: Test the performance of the circuit board under high and low temperature conditions to evaluate its thermal stability.

Humidity test: Perform humidity test to check the reliability of the circuit board in a humid environment.

Vibration test: Simulate the vibration environment in actual use to test the seismic performance of the circuit board.

Implementation strategy: Perform comprehensive environmental testing on the product to ensure that it can work stably under various environmental conditions and improve the reliability of the product.

Summary

Improving product reliability in PCBA processing involves many aspects, including design optimization, material selection, process control, quality inspection and environmental testing. By optimizing the design, selecting high-quality materials, strictly controlling the process, and implementing multi-level quality inspection and environmental testing, the reliability and performance of the product can be effectively improved. In the PCBA processing process, comprehensive consideration of these factors will help improve product quality, reduce failure rates, and thus enhance the market competitiveness of enterprises.

-

Delivery Service

-

Payment Options