- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

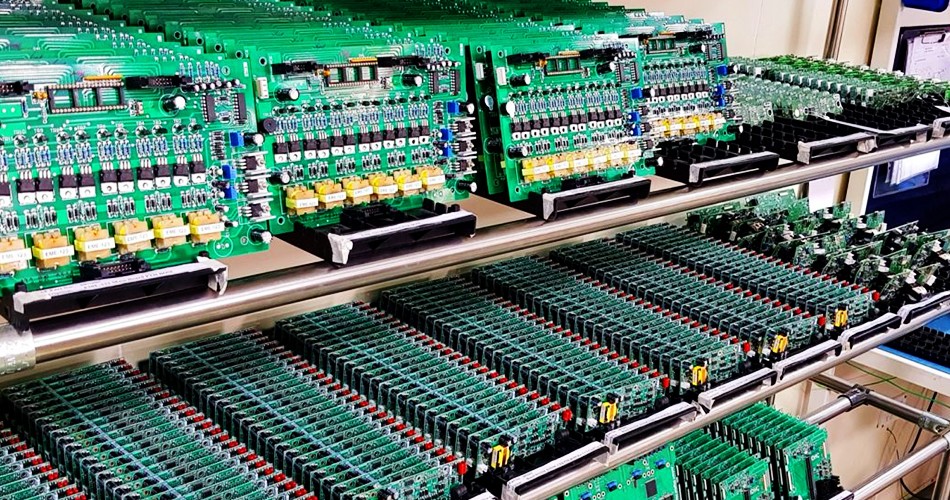

Reliability test methods in PCBA processing

2024-12-19

In the field of electronic product manufacturing, reliability testing of PCBA processing (Printed Circuit Board Assembly) is a key link to ensure product quality and stable performance. This article will discuss the reliability test methods in PCBA processing, including test purposes, common test methods and test precautions.

1. The importance of reliability testing

1.1 Ensure product quality

Reliability testing can find potential quality problems and defects to ensure that the product is stable and reliable during use.

1.2 Improve product reliability

Through reliability testing, the reliability and durability of the product can be improved to meet the user's requirements for product quality.

1.3 Reduce after-sales service costs

Discovering product problems in advance can reduce after-sales service costs and maintenance costs and improve customer satisfaction.

2. Reliability test methods

2.1 Temperature cycle test

By simulating the use of the product in different temperature environments, temperature cycle tests are performed to test the performance and stability of the product in high and low temperature environments.

2.2 Wet and hot cycle test

Simulate the use conditions in high temperature and high humidity environment, conduct wet and hot cycle test, and test the durability and stability of the product in a humid environment.

2.3 Vibration test

Through vibration test, test the vibration resistance and stability of the product during transportation and use, and ensure that the product works normally in a vibration environment.

2.4 Impact test

Simulate the impact of the product during transportation and use, conduct impact test, and test the impact resistance and structural stability of the product.

2.5 Electrical test

Conduct electrical test to test the electrical performance and stability of the product, including voltage test, current test, withstand voltage test, etc.

3. Reliability test precautions

3.1 Test environment

When conducting reliability test, it is necessary to select appropriate test environment and conditions to ensure the authenticity and reliability of the test results.

3.2 Sample selection

Select representative and sufficient samples for reliability test to ensure that the test results are representative and credible.

3.3 Test parameters

Set appropriate test parameters and test standards, determine the test plan according to product characteristics and requirements, and ensure that the test results meet product requirements.

3.4 Data analysis

Perform data analysis and statistics on the test results, find problems and optimization space, formulate and implement improvement plans, and continuously improve product reliability and stability.

4. Application case

An electronic manufacturing company conducted temperature cycle tests and vibration tests during PCBA processing and found that the product had performance degradation problems in high temperature environments. By optimizing materials and structural design, the product's high temperature resistance and stability were successfully improved.

Conclusion

Reliability testing in PCBA processing is a key link to ensure product quality and stable performance. Enterprises should select appropriate reliability testing methods based on product characteristics and requirements, strictly implement test standards and processes, continuously improve product design and manufacturing processes, and improve product reliability and competitiveness.

-

Delivery Service

-

Payment Options