- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

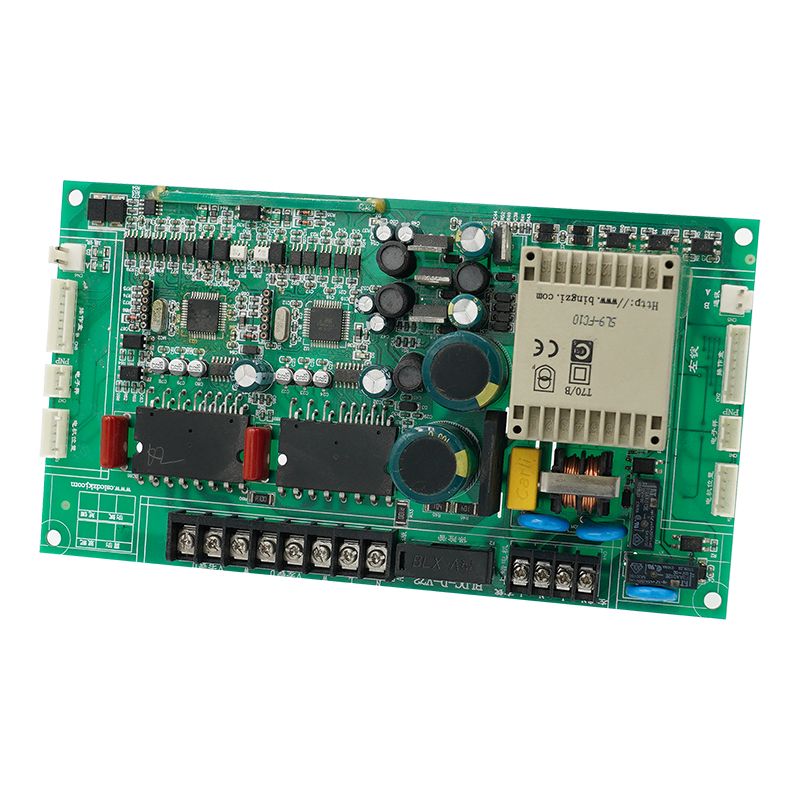

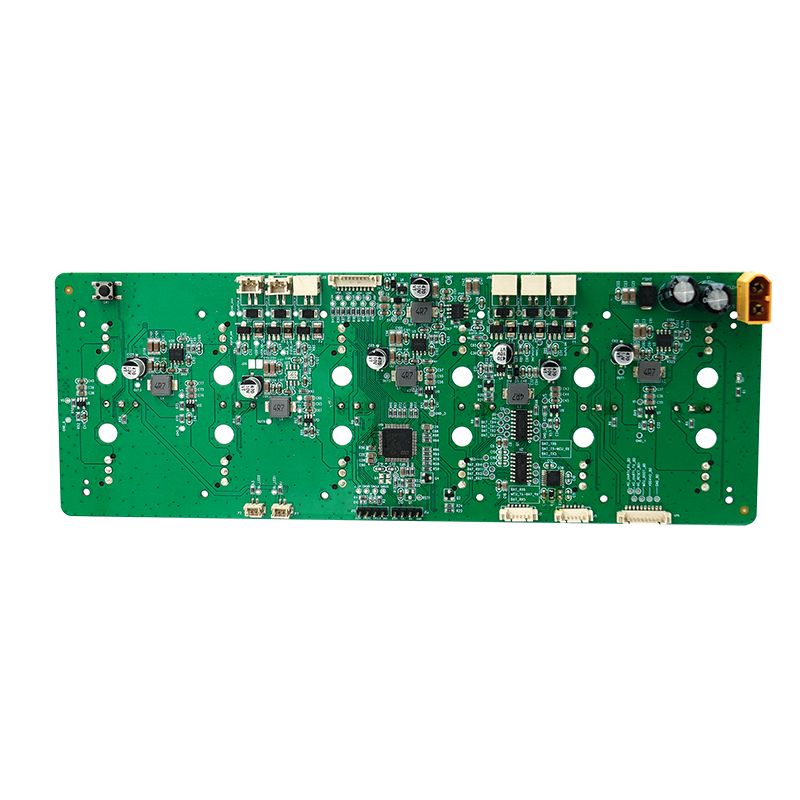

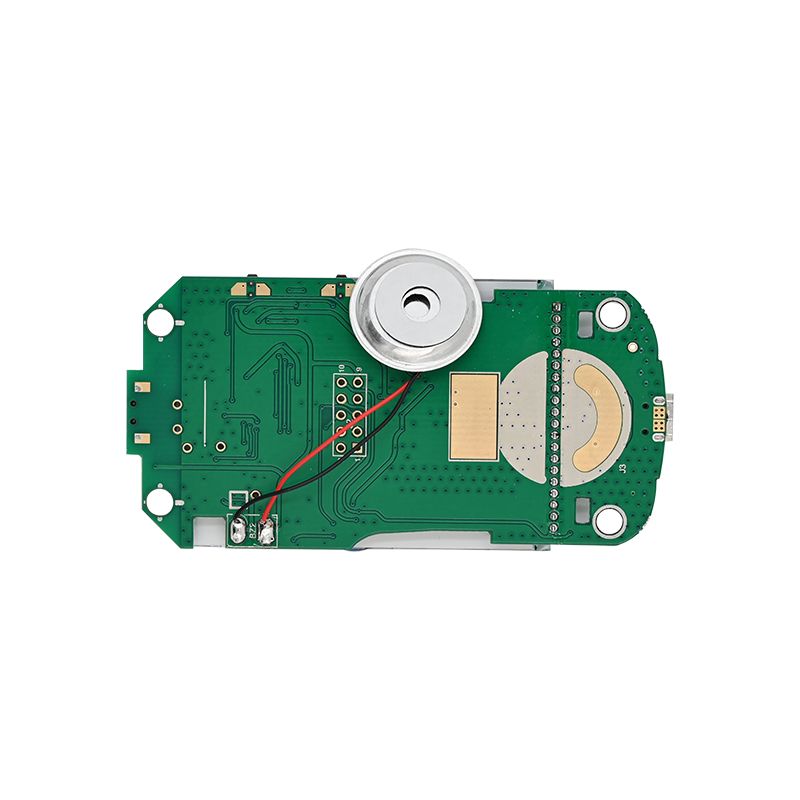

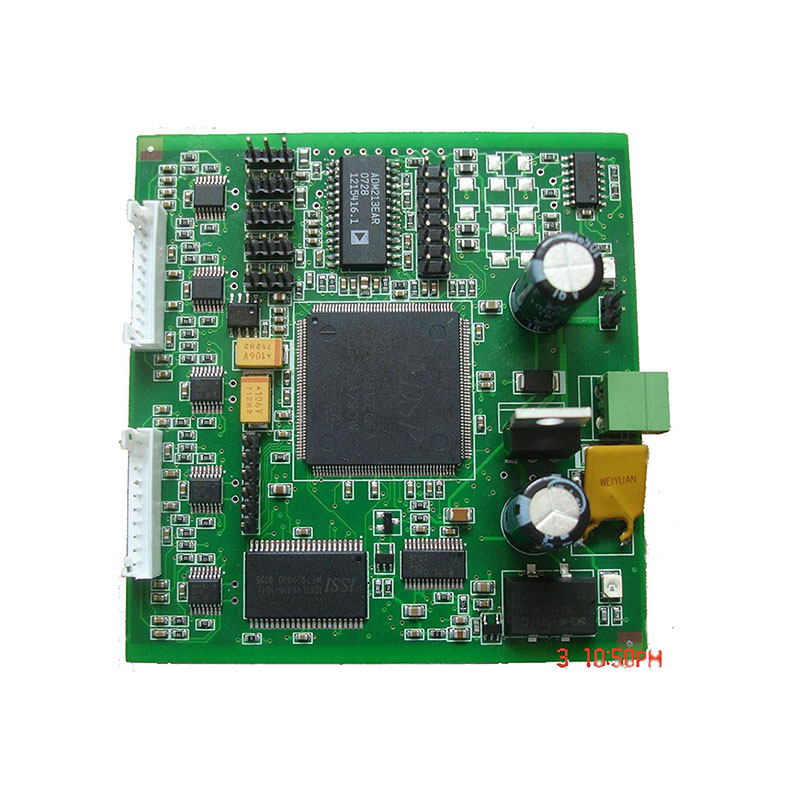

Electric Side Step PCBA

Unixplore Electronics has been dedicated to designing and producing high quality electric side step PCBA in China since 2008 with certification of ISO9001:2015 and PCB assembly standard IPC-610E.

Send Inquiry

Product Description

How to find a reliable supplier for your Electric Side Step PCBA control board?

If you are looking for a comprehensive selection of electric side step PCBA made in China, Unixplore Electronics is your ultimate source. Their products are very competitively priced and come with top-notch after-sales service. In addition, they actively seek mutually beneficial partnerships.

The electric side step is a kind of electric device designed for SUV. It has the following characteristics:

Easy to use: The electric side step can be automatically stretched and put away without manual operation, which is convenient for drivers and passengers to get on and off.

Easy maintenance: use electric help to reduce the mechanical transmission part, reduce the failure rate, and facilitate maintenance.

High -intensity materials: Made with high-intensity materials, it can withstand the pressure of heavy objects to ensure that the side step is not easy to deform.

Multiple protection: equipped with multiple protection functions, such as overload protection, anti -slip protection, etc., ensuring the safety of personnel and vehicles.

Applicable multiple models: it is suitable for various types of SUV models, which is convenient for owners to choose according to their own needs.

In short, the SUV electric side step is a convenient, safe and practical device, which provides drivers and passengers with a better way to get on and off the SUV.

The design of the electric side step PCBA needs to consider the following factors:

Structure and size of the side step, including the area and height of the side step, the anti -slip design, etc.

Material and surface treatment, such as high -strength materials, wear -resistant materials, as well as surface treatment such as non-slip and anti-corrosion.

Movement control, including the telescopic, rotation and other actions of the side step, as well as the corresponding driving mechanism and control circuit.

Electrical connection and signal transmission of the side step, such as the connection with the vehicle power and signal interface, and the transmission and feedback of the side step state signal.

Safety protection, such as overload protection, anti -slip protection and other functions to ensure the safety of personnel and vehicles.

Unixplore provides one-stop turnkey service for your EMS project. Feel free to contact us for your board building, we can make a quotation in 24 hours after we receive your Gerber file and BOM list!

The electric side step is a kind of electric device designed for SUV. It has the following characteristics:

Easy to use: The electric side step can be automatically stretched and put away without manual operation, which is convenient for drivers and passengers to get on and off.

Easy maintenance: use electric help to reduce the mechanical transmission part, reduce the failure rate, and facilitate maintenance.

High -intensity materials: Made with high-intensity materials, it can withstand the pressure of heavy objects to ensure that the side step is not easy to deform.

Multiple protection: equipped with multiple protection functions, such as overload protection, anti -slip protection, etc., ensuring the safety of personnel and vehicles.

Applicable multiple models: it is suitable for various types of SUV models, which is convenient for owners to choose according to their own needs.

In short, the SUV electric side step is a convenient, safe and practical device, which provides drivers and passengers with a better way to get on and off the SUV.

The design of the electric side step PCBA needs to consider the following factors:

Structure and size of the side step, including the area and height of the side step, the anti -slip design, etc.

Material and surface treatment, such as high -strength materials, wear -resistant materials, as well as surface treatment such as non-slip and anti-corrosion.

Movement control, including the telescopic, rotation and other actions of the side step, as well as the corresponding driving mechanism and control circuit.

Electrical connection and signal transmission of the side step, such as the connection with the vehicle power and signal interface, and the transmission and feedback of the side step state signal.

Safety protection, such as overload protection, anti -slip protection and other functions to ensure the safety of personnel and vehicles.

Unixplore provides one-stop turnkey service for your EMS project. Feel free to contact us for your board building, we can make a quotation in 24 hours after we receive your Gerber file and BOM list!

Electric Side Step PCBA Manufacture

* Gerber file and BOM list supplied by client

* Blank PCB made, components purchased by us

* PCB fabrication with parts fully assembled

* 100% Function Tested OK before shipping

* RoHS compliant, Lead-free manufacturing process

* Quick delivery, with independent ESD package

* One stop electronic manufacturing service for PCB design, PCB layout, PCB manufacture, components procurement, PCB SMT and DIP assembly, IC programming, function test, packaging and delivery

* Blank PCB made, components purchased by us

* PCB fabrication with parts fully assembled

* 100% Function Tested OK before shipping

* RoHS compliant, Lead-free manufacturing process

* Quick delivery, with independent ESD package

* One stop electronic manufacturing service for PCB design, PCB layout, PCB manufacture, components procurement, PCB SMT and DIP assembly, IC programming, function test, packaging and delivery

Unixplore PCB & PCB Assembly Capability

| Parameter | Capability |

| Layers | 1-40 layers |

| Assembly Type | Through-Hole (THT), Surface Mount (SMT), Mixed (THT+SMT) |

| Minimum Component Size | 0201(01005 Metric) |

| Maximum Component Size | 2.0 in x 2.0 in x 0.4 in (50 mm x 50 mm x 10 mm) |

| Component Package Types | BGA, FBGA, QFN, QFP, VQFN, SOIC, SOP, SSOP, TSSOP, PLCC, DIP, SIP, etc. |

| Minimum Pad Pitch | 0.5 mm (20 mil) for QFP, QFN, 0.8 mm (32 mil) for BGA |

| Minimum Trace Width | 0.10 mm (4 mil) |

| Minimum Trace Clearance | 0.10 mm (4 mil) |

| Minimum Drill Size | 0.15 mm (6 mil) |

| Maximum Board Size | 18 in x 24 in (457 mm x 610 mm) |

| Board Thickness | 0.0078 in (0.2 mm) to 0.236 in (6 mm) |

| Board Material | CEM-3,FR-2,FR-4, High-Tg, HDI, Aluminum, High Frequency, FPC, Rigid-Flex, Rogers, etc. |

| Surface Finish | OSP, HASL, Flash Gold, ENIG, Gold Finger, etc. |

| Solder Paste Type | Leaded or Lead-Free |

| Copper Thickness | 0.5OZ – 5 OZ |

| Assembly Process | Reflow Soldering, Wave Soldering, Manual Soldering |

| Inspection Methods | Automated Optical Inspection (AOI), X-ray, Visual Inspection |

| Testing Methods In-House | Functional Test, Probe Test, Aging Test, High and Low Temperature Test |

| Turnaround Time | Sampling: 24 hours to 7 days, Mass Run: 10 - 30 days |

| PCB Assembly Standards | ISO9001:2015; ROHS, UL 94V0, IPC-610E class ll |

Unixplore Value-Added EMS Service

● IC pre-programming service with file in format of HEX,ELF and BIN.

● Electric Side Step PCBA Function test fixture customized according to client’s test requirements

● Box building service including plastic & metal case mold and part production

● Conformal coating including selective lacquer coating, epoxy resin potting

● Wire harness and cable assembly

● Finished product assembly including box, screen, membrane switch, labelling and customized carton or retail box packing.

● Various third-party tests for PCBA are available upon request

● Product Certification Assistance

● Electric Side Step PCBA Function test fixture customized according to client’s test requirements

● Box building service including plastic & metal case mold and part production

● Conformal coating including selective lacquer coating, epoxy resin potting

● Wire harness and cable assembly

● Finished product assembly including box, screen, membrane switch, labelling and customized carton or retail box packing.

● Various third-party tests for PCBA are available upon request

● Product Certification Assistance

PCBA Production Procedure

-

1. Automatic solderpaste printing

-

2. solderpaste printing done

-

3. SMT pick and place

-

4. SMT pick and place done

-

5. ready for reflow soldering

-

6. reflow soldering done

-

7. ready for AOI

-

8. AOI inspection process

-

9. THT component placement

-

10. wave soldering process

-

11. THT assembly done

-

12. AOI Inspection for THT assembly

-

13. IC programming

-

14. function test

-

15. QC Check and Repair

-

16. PCBA conformal coating Process

-

17. ESD packing

-

18. Ready for Shipping

Packaging

For PCBA

For Finished Product

Hot Tags: Electric Side Step PCBA, China, Manufacturers, Suppliers, Factory, Customized, Cheap, Quality, Advanced, CE, 1 Year Warranty, Price

Related Category

Home Appliance PCBA

Industrial Control PCBA

Automobile PCBA

Consumer Electronics PCBA

Medical Equipment PCBA

Security System PCBA

Healthcare PCBA

LED Lighting PCBA

IoT PCBA

Electric Gardening Tool PCBA

Send Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.